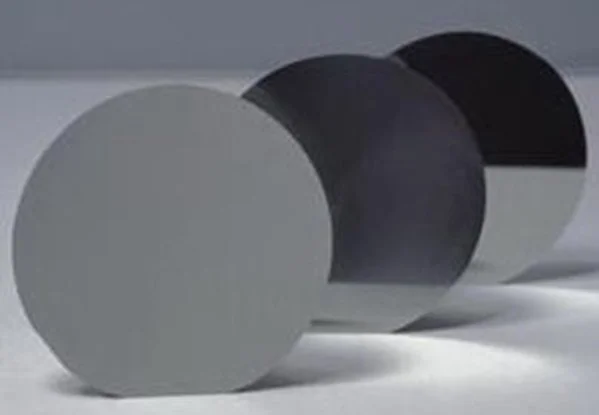

Semiconductor Wafers

Semiconductor wafers are foundational components in the electronics industry, serving as the substrate for the fabrication of integrated circuits (ICs) and other semiconductor devices. These wafers are typically thin, disc-shaped slices made from a single crystal or polycrystalline material, with silicon being the most widely used due to its excellent semiconductor properties. Silicon wafers play a pivotal role in the production of microelectronics, enabling the creation of the intricate circuitry that powers a vast array of electronic devices.

The manufacturing process of semiconductor wafers involves several critical steps. First, a single crystal ingot of high-purity sapphire, germanium, silicon or silicon carbide is sliced into thin wafers using a precision saw. These wafers undergo a series of chemical and mechanical processes to achieve a smooth, flat surface and consistent thickness. The resulting wafers serve as the canvas for the creation of semiconductor devices through photolithography, etching, and deposition processes.

Semiconductor wafers come in various sizes, with diameters ranging from a few inches to over a foot, and their dimensions play a crucial role in determining the number of devices that can be produced in a single manufacturing run. The wafer's surface is typically polished to an ultra-smooth finish to ensure uniformity in subsequent processes.

These wafers are the platform upon which intricate patterns of transistors, resistors, and interconnects are created during the semiconductor fabrication process. The properties of the semiconductor material, as well as the precision in wafer manufacturing, directly impact the performance and reliability of the electronic components produced. Semiconductor wafers are essential in driving technological advancements across various industries, from consumer electronics to healthcare, automotive, and beyond, making them a critical element in the modern digital age.