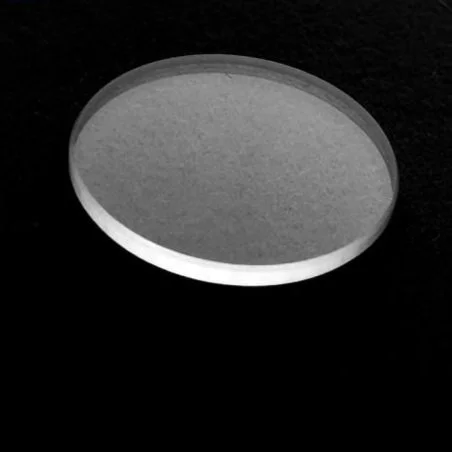

Optical Diffusers

Optical diffusers are precision-engineered components designed to scatter light uniformly, enabling consistent illumination and accurate calibration in optical systems. Widely used in aerospace, medical imaging, and remote sensing, these diffusers ensure optimal light distribution while maintaining superior performance under demanding conditions, including extreme temperatures and radiation exposure.

Firebird Optics specializes in manufacturing high-performance optical diffusers tailored to meet the needs of advanced optical systems. Crafted using Diffusil from IQS GmbH, the highest-grade fused silica material in the world, our diffusers deliver exceptional thermal stability, uniform light scattering, and resistance to radiation and contamination. These features make them indispensable for critical applications like Earth observation, aerospace instrumentation, and high-precision laboratory environments.