Firebird Optics Awarded Contract to Supply Custom Optical Waveplates for West Point’s Laser and Optics Teaching Lab

/Firebird Optics has been awarded contract W911SD25PA066 to design and manufacture custom optical waveplates for the United States Military Academy West Point. This project supports the Academy’s Laser and Optics Teaching Lab, a vital component of its Photonics Research Center. The award underscores Firebird Optics’ reputation for delivering precision-engineered optical components that meet the demanding requirements of military, research, and advanced education environments.

A Partnership in Precision and Innovation

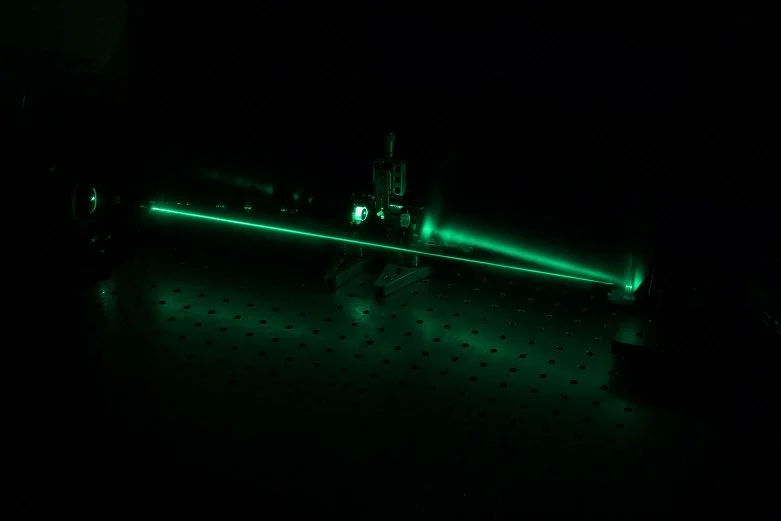

The West Point Photonics Research Center is recognized for its work in advancing optical science, integrating laser systems, and developing novel photonics applications. The center’s Laser and Optics Teaching Lab serves as a cornerstone for educating cadets in high-level optical engineering, laser alignment, polarization control, and wavefront manipulation.

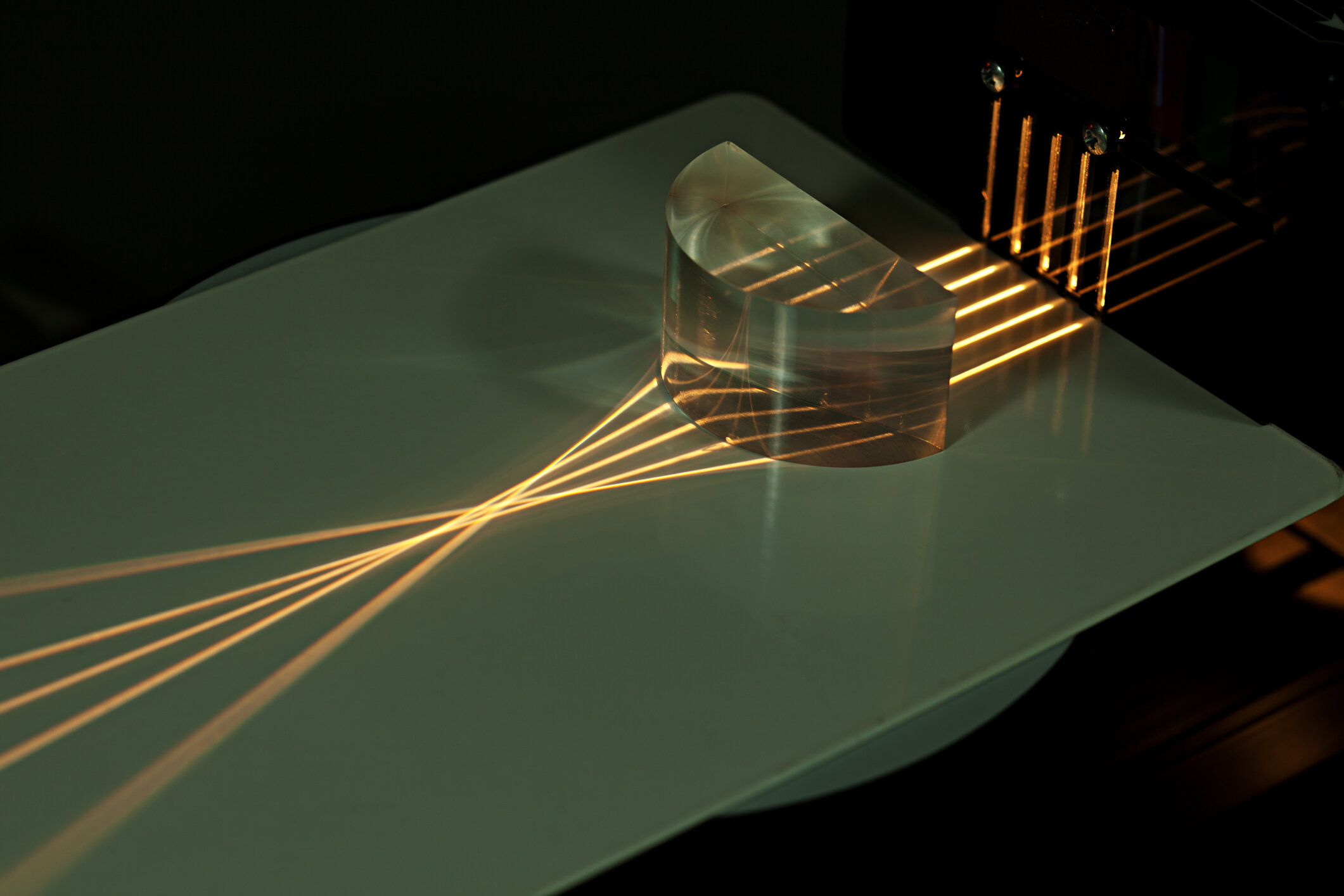

By manufacturing the custom optical waveplates for this lab, Firebird Optics is providing cadets with hands-on access to components that meet the highest optical and mechanical performance standards. These waveplates will be used for tasks such as precise polarization control, laser beam conditioning, and advanced optical experiments, giving students the opportunity to work with the same grade of components found in cutting-edge military, space, and industrial systems.

Technical Rigor and Manufacturing Excellence

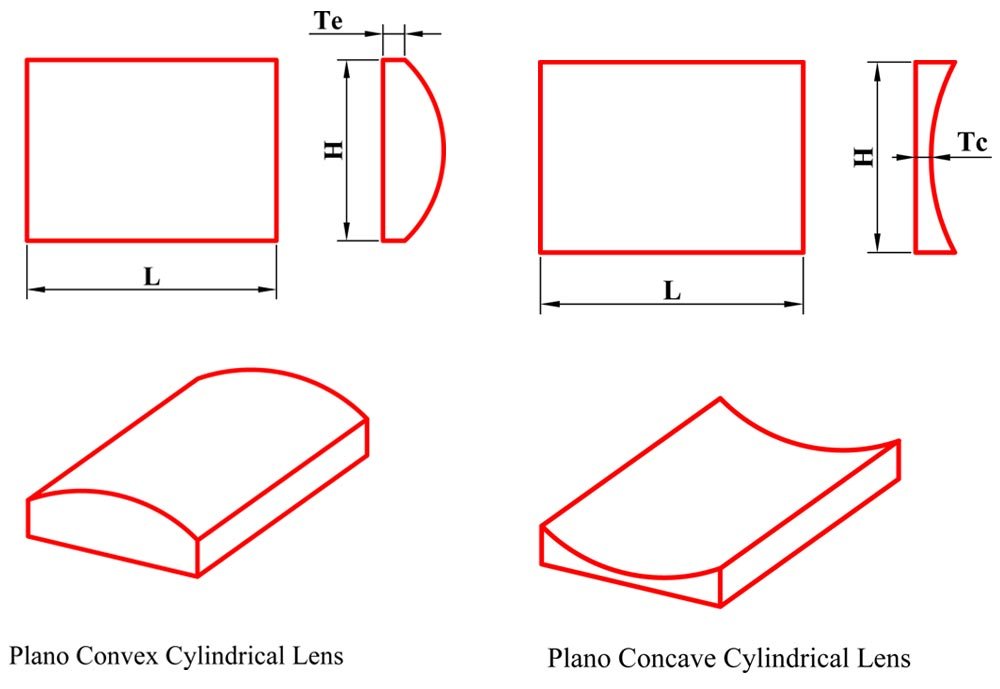

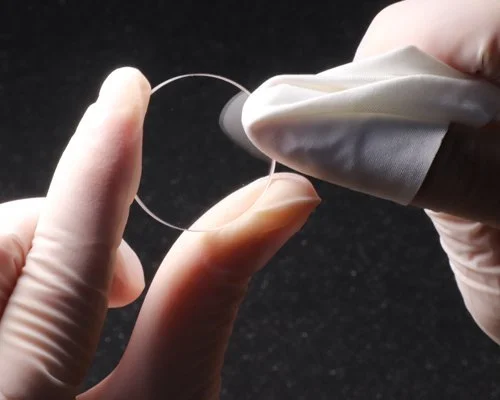

Producing an optical waveplate for an environment as demanding as West Point’s requires a combination of advanced materials, precision fabrication, and meticulous quality control. Firebird Optics’ waveplates are typically made from high-grade fused silica or crystalline quartz, selected for their optical clarity, durability, and resistance to thermal and mechanical stress.

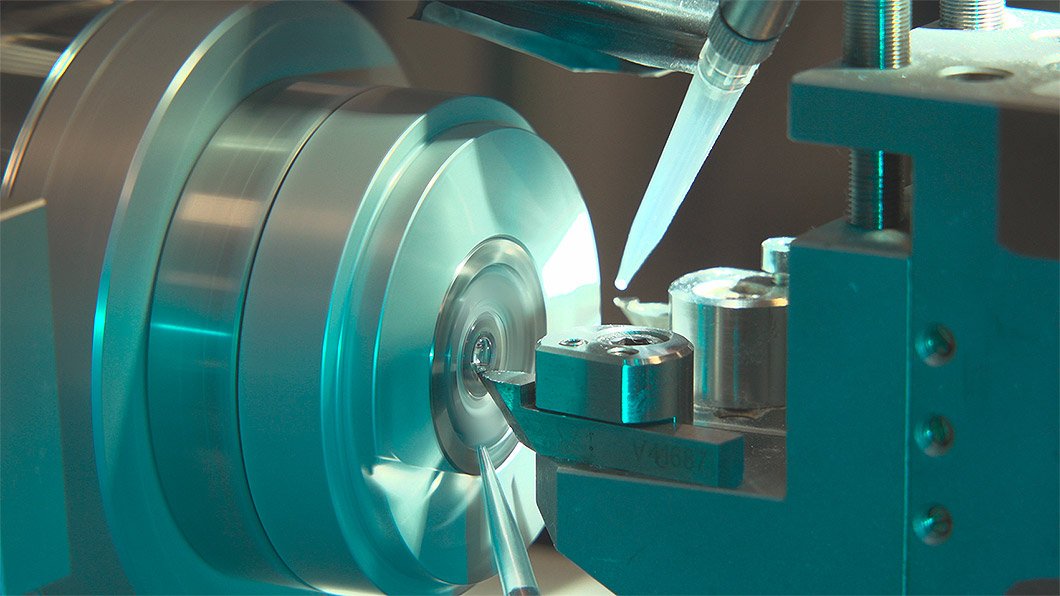

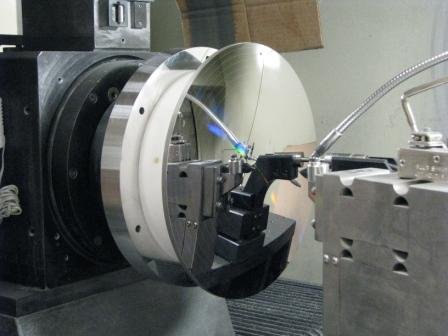

Every waveplate undergoes precision polishing to sub-micron flatness, ensuring minimal wavefront distortion. The retardance value—whether quarter-wave, half-wave, or custom-specified—is fine-tuned with interferometric measurement systems, ensuring exact performance at the target wavelength. Coatings are applied using advanced deposition techniques to optimize transmission while minimizing reflection losses across the designated spectral range.

The result is a waveplate that maintains exceptional stability under varying environmental conditions, from the controlled lab environment to potential field applications. For West Point, this translates into reliable, repeatable performance in training exercises and research projects alike.

Enabling the Next Generation of Optical Leaders

The Laser and Optics Teaching Lab is not just a place for coursework—it’s where future military leaders gain deep technical proficiency in technologies critical to modern defense systems. Waveplates play a central role in teaching principles of polarization optics, allowing cadets to explore concepts such as birefringence, phase retardation, and polarization-dependent interference.

Firebird Optics’ contribution ensures these students train with professional-grade optical hardware, preparing them to excel in both operational and research roles. This aligns directly with West Point’s mission to develop leaders of character who are equipped with both tactical and technical expertise.

Commitment to Quality and Service

As with all projects, Firebird Optics stands behind the performance of its components. The manufacturing process follows rigorous ISO 9001:2015 quality standards, with every waveplate inspected for dimensional accuracy, retardance precision, and surface quality. Packaging, handling, and delivery are carried out in accordance with MIL-SPEC requirements, ensuring the waveplates arrive at West Point in pristine condition.

This contract, W911SD25PA066, reflects Firebird Optics’ ability to deliver optical waveplates that meet the highest standards of precision optics while supporting mission-critical training and research objectives. It also reinforces the company’s position as a trusted partner for military and research institutions worldwide.

mean green laser machine