X-Ray Optics

X-ray optics, essential for manipulating x-ray beams, include components like beryllium windows, silicon mirrors, and diamond windows, each serving specific roles. Beryllium windows are ideal for maintaining vacuum conditions while allowing high-energy x-rays to pass due to their transparency and durability. Silicon mirrors provide precise reflection and focusing of x-rays, leveraging their smoothness and thermal stability. Diamond windows, with exceptional thermal conductivity and low x-ray absorption, handle high-intensity radiation, making them ideal for demanding applications like synchrotrons, which use these components for beamline focusing and material characterization.

Kirkpatrick-Baez X-Ray Mirrors

Kirkpatrick-Baez X-Ray Mirrors

Kirkpatrick-Baez (K-B) mirrors are advanced optical devices used to precisely focus X-ray beams. Comprising two reflective surfaces oriented perpendicularly, these mirrors can manipulate X-rays to converge at a single focal point. This unique design makes them indispensable in synchrotron beamlines, X-ray microscopes, and imaging systems where accuracy and clarity are paramount. The versatility of K-B mirrors allows them to cater to a range of X-ray applications, from materials analysis to biological imaging, by tailoring the beam size and intensity to experimental needs.

Silicon mirrors play a pivotal role in K-B systems due to their outstanding material properties. Silicon substrates are favored for their smooth surface quality, high thermal stability, and compatibility with precision polishing techniques. When coated with reflective materials such as gold or platinum, silicon mirrors achieve optimal performance across a wide range of X-ray wavelengths, ensuring minimal energy loss and superior focusing capabilities. This makes silicon mirrors particularly well-suited for experiments requiring nanometer-scale precision and adaptability across diverse synchrotron applications.

At Firebird Optics, we specialize in crafting custom silicon mirrors for Kirkpatrick-Baez assemblies. Leveraging advanced manufacturing techniques, we ensure each mirror is optimized for its intended energy range and beamline application. Whether for synchrotron facilities or cutting-edge research laboratories, our silicon mirrors deliver unmatched precision, reliability, and durability.

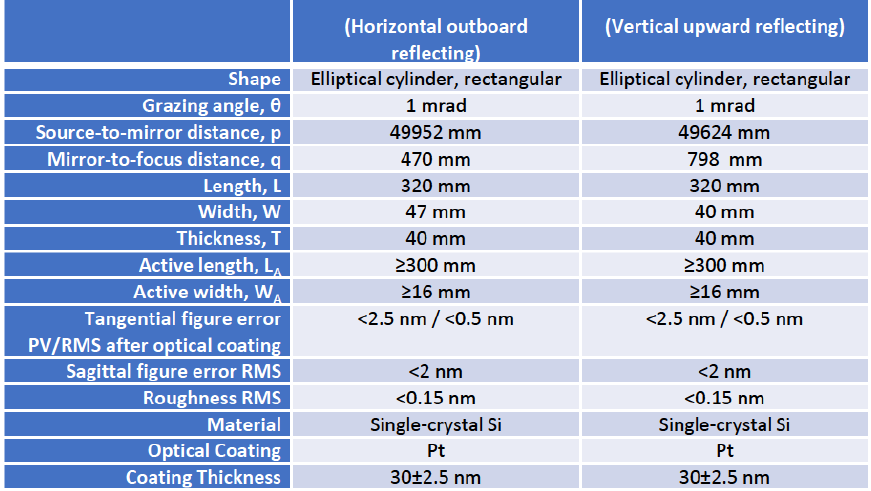

Technical Details for Standard Kirkpatrick-Baez Mirror Set:

Kirkpatrick-Baez Mirrors: A Game-Changer in X-Ray Science

Kirkpatrick-Baez (K-B) mirrors are optical components that have revolutionized X-ray science by enabling precise control and focusing of X-ray beams. Their innovative design and exceptional performance have made them integral to applications ranging from material science to biology. This article explores the history, challenges in manufacturing, and the cutting-edge applications of these mirrors, highlighting their transformative impact on science and technology.

The Origins of K-B Mirrors

The concept of K-B mirrors was developed in 1948 by Paul Kirkpatrick and Albert Baez, who proposed using two perpendicular reflective surfaces to focus X-rays onto a single point. This geometry allowed for unprecedented control over X-ray beams, addressing the challenge of focusing highly energetic photons with precision. Over the years, their design has been refined, becoming a cornerstone of advanced optical systems in X-ray science.

Today, K-B mirrors are extensively used in synchrotron facilities and X-ray free-electron lasers (XFELs). Their ability to manipulate X-rays down to nanometer-scale spots has enabled groundbreaking research in structural biology, semiconductor analysis, and nanotechnology.

The Challenge of Manufacturing K-B Mirrors

Producing K-B mirrors is no small feat. The key challenges lie in achieving the ultra-smooth surface finish and precise curvature required for optimal performance. Any imperfections can scatter X-rays, reducing the system's efficiency and accuracy. Silicon is a preferred substrate due to its mechanical stability, thermal resistance, and compatibility with advanced polishing techniques.

Coating the mirrors with materials like gold or platinum enhances their reflectivity, especially at grazing incidence angles. This process requires precise deposition techniques to ensure uniformity and adherence. The final step involves rigorous testing and alignment, as even minor deviations can significantly impact the mirror's focusing ability.

Exciting Applications of K-B Mirrors

1. Synchrotron Beamlines

Synchrotrons generate intense X-ray beams used for material and chemical analysis. K-B mirrors focus these beams to microscopic scales, enabling scientists to explore atomic structures, study phase transitions, and analyze complex materials with high resolution.

2. Structural Biology

In structural biology, K-B mirrors facilitate protein crystallography by focusing X-rays onto tiny biological samples. This precision helps researchers determine protein structures, which is crucial for drug development and understanding biological processes.

3. Nanotechnology and Semiconductor Research

K-B mirrors are pivotal in inspecting nanoscale features in semiconductors. Their ability to deliver highly focused beams supports the development of next-generation microchips and other nano-engineered materials.

4. Medical Imaging and Therapy

Emerging applications include their use in advanced X-ray imaging systems and cancer therapies. Their precision can improve imaging resolution and enable targeted radiation treatments with minimal impact on surrounding tissues.

Future Innovations

The field of K-B mirror technology is evolving rapidly, with researchers exploring new materials, such as multilayer coatings, to enhance performance. Efforts are also being made to develop adaptive K-B mirrors that can dynamically adjust their curvature to cater to variable experimental conditions. These advancements promise to unlock even more possibilities in X-ray science and its applications across industries