Vacuum Viewports

Vacuum viewports are specialized windows or ports integrated into vacuum systems, allowing visual observation or the transmission of light into or out of a vacuum chamber without compromising the vacuum environment. Firebird Optics offers viewports made from glass, fused silica, sapphire, ZnSe, CVD diamond and many more as well as a variety of flanges. All setups are designed to withstand the vacuum pressure and maintain optical clarity. They are sealed with high-quality, vacuum-compatible gaskets or welds to ensure they do not leak.

These viewports are essential in various fields, including materials science, semiconductor manufacturing, and fundamental physics research, where maintaining a controlled vacuum environment is crucial.

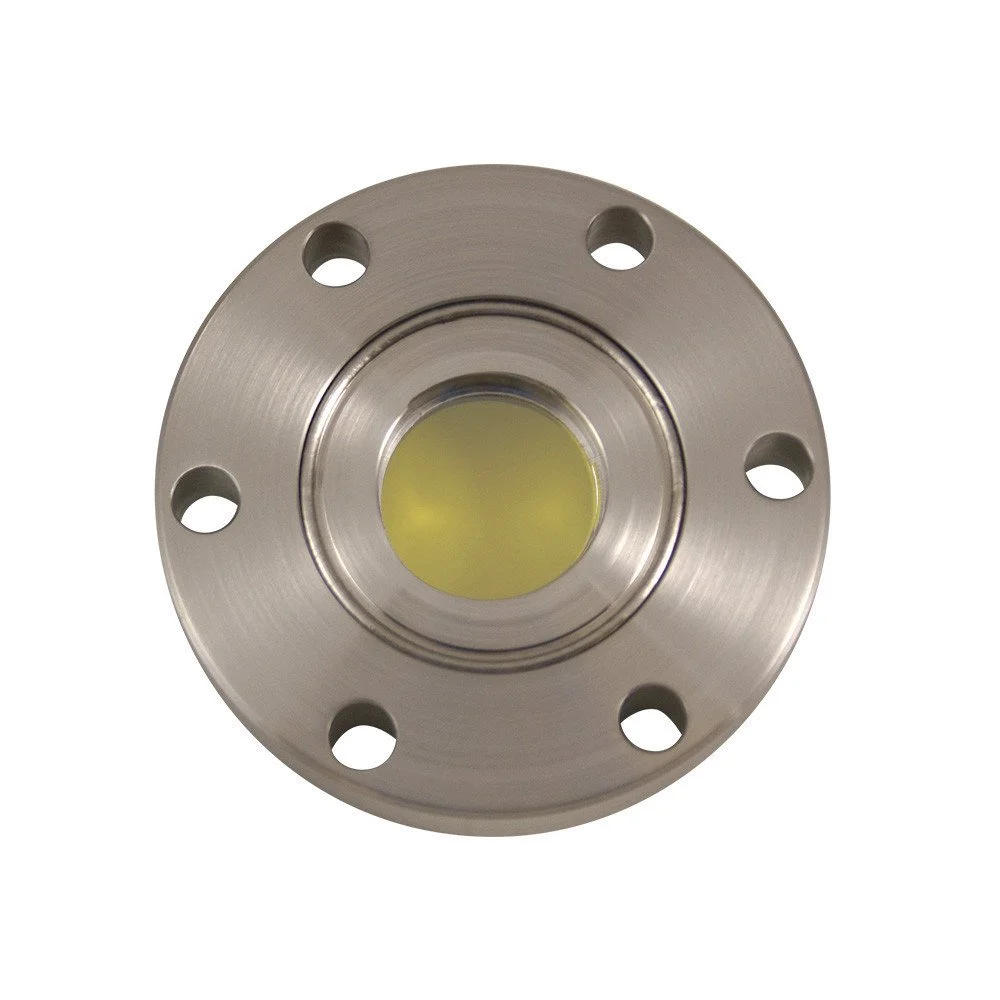

CF Flanged Zinc Selenide (ZnSe) Viewports

CF Flanged Zinc Selenide (ZnSe) Viewports

Zinc Selenide (ZnSe) UHV viewports are specialized windows used in ultra-high vacuum systems, notable for their excellent transmission properties in the infrared spectrum. These viewports provide clear optical access while maintaining vacuum integrity, making them ideal for applications involving IR lasers and spectroscopy. Due to their good thermal stability and chemical resistance, ZnSe viewports are widely used in research and industrial settings requiring precise IR optical measurements and high-temperature processes.

Standard Specifications of CF Flanged Zinc Selenide Viewports:

Features high-grade Firebird Optics Zinc Selenide (ZnSe) windows.

CF Flanges and sleeves made from 304L SS for UHV compatibility. Other materials available upon request.

Viewports sealed with fully annealed copper gaskets, which serve to reduce strain.

Three standard view area sizes of 10.2mm (DN16CF- 33.78mm OD), 22.9mm (DN35CF-DN40CF- 69.85mm OD) and 47.8mm (DN63F- 114.3mm OD) available. Custom sizes available upon request.

Flatness: 1λ @ 632nm Transmitted Wavefront

Surface finish: 40/20 Scratch-Dig

Handling and Applications Guide for CF-Flanged Zinc Selenide Viewports

CF-flanged Zinc Selenide (ZnSe) viewports are critical components in ultra-high vacuum (UHV) systems, known for their excellent infrared transmission properties and high resistance to thermal shock. These viewports are designed to provide reliable optical access while maintaining the integrity of the vacuum environment, making them indispensable in various scientific and industrial applications.

Handling Instructions

Maintain a Clean Environment: Handle viewports in a clean room or a controlled, dust-free environment to prevent contamination.

Wear Protective Gloves: Always use clean, lint-free gloves to avoid transferring oils and dirt onto the viewports.

Use Proper Handling Tools: Utilize appropriate tools, such as cleanroom-compatible tweezers or vacuum fixtures, to handle the viewports without touching the optical surfaces.

Avoid Direct Contact: Handle the viewport by the CF flange or edges to prevent fingerprints and smudges on the optical surfaces.

Support During Installation: When installing the viewport into a CF flange, ensure it is properly supported. Use a compatible gasket and tighten the bolts evenly to distribute pressure and avoid stressing the material.

Safety Precautions

Handle with Care: ZnSe is strong but brittle. Avoid dropping or applying sudden mechanical stress to prevent chipping or cracking.

Temperature Gradients: Be cautious of rapid temperature changes. Gradual heating and cooling are recommended to prevent thermal shock.

Chemical Exposure: ZnSe has good chemical resistance but prolonged exposure to strong acids or bases should be avoided. Clean only with recommended solvents.

Protective Gear: Use appropriate protective gear such as gloves and safety glasses when handling viewports to prevent injury from accidental breakage or chemical exposure.

Storage: Store viewports in a protective case or clean, padded container when not in use. Ensure the storage area is dry and free from contaminants.

Applications

Infrared Spectroscopy: ZnSe viewports are ideal for infrared spectroscopy applications due to their excellent IR transmission properties.

Laser Systems: These viewports are commonly used in laser systems, particularly CO2 lasers, where high transparency in the IR range is essential.

Thermal Imaging: The high thermal stability of ZnSe makes these viewports suitable for thermal imaging and other applications involving high temperatures.

Research Laboratories: ZnSe viewports are extensively used in research labs for various experiments requiring precise optical measurements and high vacuum conditions.

Industrial Processing: In industries such as semiconductor manufacturing, ZnSe viewports provide reliable optical access for monitoring and controlling processes.

Maintenance Tips

Regular Inspection: Periodically inspect the viewport for any signs of damage or contamination. Replace if any cracks, chips, or significant scratches are observed.

Cleaning: Clean the viewport using approved solvents and lint-free wipes. Avoid abrasive materials that could scratch the surface.

Proper Use: Ensure the viewport is used within its specified temperature and pressure limits to avoid compromising its integrity.