Optical Windows

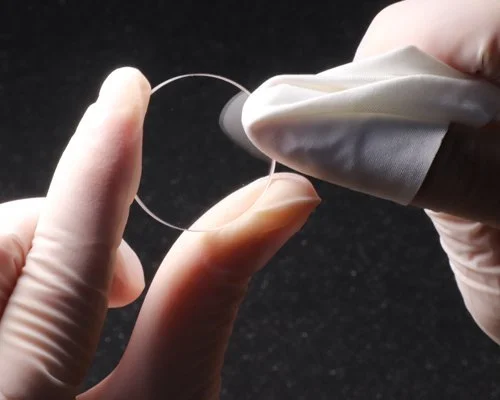

Optical windows are transparent components made of materials like glass or crystal that are used to protect and control the flow of light in optical systems. IR windows and optics for use in FTIR Spectroscopy and CO2 lasers. This includes discs, rectangular plates and various other geometries.

In various fields, optical windows serve many purposes. They act as protective barriers, shielding sensitive optical components from environmental factors such as dust, moisture, and contaminants. Additionally, they enable the transmission of light while minimizing distortion, reflection, and absorption, thus maintaining the integrity of the optical system.

Optical windows are employed in a wide range of applications, including scientific research, industrial manufacturing, aerospace, defense, and telecommunications. They are utilized in optical instruments like cameras, microscopes, telescopes, lasers, and sensors. By providing a stable optical interface, optical windows facilitate accurate measurements, imaging, and analysis of light, enabling advancements in numerous fields.

Optical windows come in many shapes and sizes but a major factor is their material. The types of materials that an optical window is constructed from dictate the wavelengths (measured in nm) that they can view. In IR It is extremely important that selecting the right material is done to avoid many a headache and a waste of money and time.

If you are having choice fatigue and are getting overwhelmed by all the options please check out our optical window guide.

Zinc Sulfide (ZnS) Windows

Zinc Sulfide (ZnS) Windows

Zinc Sulfide or Zinc Sulphide (ZnS) has an IR transmission range of 8-14 microns and is best used in a variety of applications from thermal imaging, FLIR and medical systems.

Firebird provides these in several uncoated stock configurations but can provide customized and coated to your specifications.

Zinc Sulfide (ZnS Basics):

Zinc sulfide (ZnS) windows are a type of optical window used in a variety of applications that require high optical clarity and thermal stability. ZnS is a semi-transparent material with a wide transmission range from the ultraviolet to the infrared spectrum. It is commonly used in a variety of optical applications, including imaging, spectroscopy, and laser systems.

The basic construction of ZnS windows involves shaping and polishing the material to a high degree of precision to achieve the desired optical properties. ZnS windows can be manufactured using a variety of techniques, including hot pressing, chemical vapor deposition (CVD), and physical vapor deposition (PVD). PVD is the most commonly used method for producing high-quality ZnS windows, as it allows for precise control over the thickness and uniformity of the coating.

One of the key advantages of ZnS windows is their high refractive index, which is approximately 2.3. This means that ZnS windows can bend light to a greater degree than other materials with a lower refractive index, such as glass. This property is useful in applications that require precise control over the direction of light, such as in laser cavities and imaging systems.

ZnS windows are also highly durable and resistant to damage. They have good resistance to scratching and abrasion, and can be used in a variety of environmental conditions, including high-temperature and high-pressure environments. This makes them an excellent choice for aerospace and defense applications, such as thermal imaging systems, missile guidance systems, and laser range finders.

One potential limitation of ZnS windows is their relatively low hardness compared to some other materials. While ZnS is relatively hard and durable, it is still susceptible to scratching and damage, particularly when exposed to abrasive materials. As a result, care must be taken during handling and cleaning to avoid damage to the surface of the window.

Why Use Zinc Sulfide Over Zinc Selenide?

When choosing between zinc sulfide (ZnS) and zinc selenide (ZnSe) windows for an optical application, several factors need to be considered. Both materials are commonly used as optical windows because of their wide transmission range from the ultraviolet to the infrared spectrum and their high refractive index. However, there are some differences between the two materials that may make one more suitable than the other for certain applications.

One of the main differences between ZnS and ZnSe is their hardness. ZnS is a relatively hard material, with good resistance to scratching and abrasion, while ZnSe is a relatively soft material that is more susceptible to scratching and damage. This makes ZnS windows a better choice for applications where durability and resistance to damage are important, such as in high-temperature and high-pressure environments.

Another important consideration is the transmission range of the materials. ZnS has a wider transmission range than ZnSe, extending further into the ultraviolet region. This makes ZnS windows a better choice for applications that require high transmission in the ultraviolet region, such as in UV imaging systems or UV spectroscopy.

In terms of cost, ZnS is generally less expensive than ZnSe, which may make it a more attractive choice for applications where cost is a major consideration.

Overall, the choice between ZnS and ZnSe windows will depend on the specific requirements of the application, including the desired transmission range, durability, and cost. ZnS windows are generally a better choice for applications where durability and resistance to damage are important, while ZnSe windows are better suited for applications that require high transmission in the infrared region.

ZnS Transmission

| Wavelength range: 8-14µm | Coating: Uncoated |

|---|---|

| Diameter tolerance: ±0.13mm | Surface Quality: 60/40 |

| Thickness tolerance: ±0.13mm | Paralellism: <3 arc minute |

| Clear Aperture: 90% | Density: 4.09g/cm3 | Melting point: 1827ºC | Young's Modulus: (GPa): 74.5 | Coefficient of Thermal Expansion: 7.3 x 10-6/°C | Knoop Hardness: 250kg/mm2 |

Finding the right optical window can be an exercise in choice fatigue. Let us help!