Optical Windows

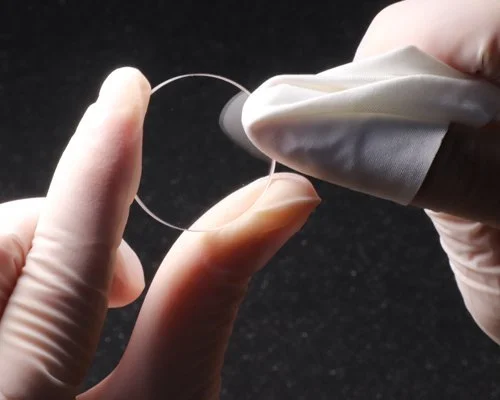

Optical windows are transparent components made of materials like glass or crystal that are used to protect and control the flow of light in optical systems. IR windows and optics for use in FTIR Spectroscopy and CO2 lasers. This includes discs, rectangular plates and various other geometries.

In various fields, optical windows serve many purposes. They act as protective barriers, shielding sensitive optical components from environmental factors such as dust, moisture, and contaminants. Additionally, they enable the transmission of light while minimizing distortion, reflection, and absorption, thus maintaining the integrity of the optical system.

Optical windows are employed in a wide range of applications, including scientific research, industrial manufacturing, aerospace, defense, and telecommunications. They are utilized in optical instruments like cameras, microscopes, telescopes, lasers, and sensors. By providing a stable optical interface, optical windows facilitate accurate measurements, imaging, and analysis of light, enabling advancements in numerous fields.

Optical windows come in many shapes and sizes but a major factor is their material. The types of materials that an optical window is constructed from dictate the wavelengths (measured in nm) that they can view. In IR It is extremely important that selecting the right material is done to avoid many a headache and a waste of money and time.

If you are having choice fatigue and are getting overwhelmed by all the options please check out our optical window guide.

Silicon (Si) Windows

Silicon (Si) Windows

Silicon or Si has a good transmittance in the range of 1.2-8μm and is an ideal choice for NIR and MWIR applications. Silicon has approximately half the density (2.329g/cm3) of germanium and zinc selenide and is therefore harder and less brittle than these other IR options. This lower density also translates to a lower weight making silicon and ideal choice for weight-sensitive applications.

Silicon, with its lower cost than its IR alternatives, can be found in various military, scientific and IR imaging applications. With a resistivity of 5-40 ohms, silicon is prized for its electrical properties in semiconductor settings.

While uncoated silicon has a transmission of approximately 50% in the 1.2-8μm range, AR coatings are often needed to increase the transmission. This can be quoted on request by contacting us at info@firebirdoptics.com.

Firebird Optics provides silicon and various other materials in several uncoated stock configurations in circular and rectangular shapes but can provide them customized and coated to your specifications.

Silicon Optical Windows: A Comprehensive Overview

Silicon optical windows are integral components in a vast array of optical systems, from scientific instruments to industrial equipment. Their unique properties and versatility make them indispensable for a wide range of applications. In this article, we provide a comprehensive overview of Silicon optical windows, delving into their characteristics, advantages, and diverse applications.

Understanding Silicon Optical Windows

Silicon optical windows are optical elements made from single-crystal silicon, a widely abundant semiconductor material known for its exceptional optical properties. These windows are typically transparent across a broad spectral range, encompassing ultraviolet (UV), visible, and near-infrared (NIR) wavelengths.

Advantages of Silicon Optical Windows

Broad Spectral Range: Silicon optical windows offer excellent transmission properties across a wide spectral range, making them suitable for diverse optical applications that require multi-wavelength compatibility.

Low Dispersion: Silicon exhibits low dispersion, meaning it minimizes color aberrations and ensures precise imaging, making it ideal for applications requiring high optical clarity.

Mechanical Durability: Silicon is mechanically robust and can withstand physical stress and pressure, ensuring longevity and reliability in various operating conditions.

Thermal Stability: Silicon optical windows maintain their optical clarity even under extreme temperatures, making them valuable for applications involving high-power lasers and thermal variations.

Applications of Silicon Optical Windows

Silicon optical windows find extensive use across multiple industries and scientific disciplines:

1. Spectroscopy: Silicon windows are crucial components in UV and NIR spectroscopy instruments, facilitating the precise analysis of chemical compositions and molecular structures.

2. Imaging: They are commonly employed in cameras and imaging systems for their ability to provide clear and distortion-free images across a broad spectral range.

3. Scientific Research: Silicon optical windows are integral in laboratories for various optical experiments and research activities.

4. Solar Cells: Silicon windows are used in photovoltaic applications, enabling the efficient conversion of sunlight into electrical energy.

5. Laser Systems: They play a vital role in laser systems, ensuring minimal energy loss and maintaining beam quality.

Conclusion

Silicon optical windows, with their broad spectral compatibility, low dispersion, mechanical durability, and thermal stability, stand as versatile and essential components in the world of optics. Their applications span across scientific, industrial, and technological domains, contributing to advancements in spectroscopy, imaging, and laser technology. Understanding the properties and advantages of Silicon optical windows is pivotal for engineers, researchers, and professionals working in optics, as they continue to shape innovations in various fields.

Silicon (Si) Specs:

Transmission of uncoated Silicon windows:

General specs:

| Wavelength range: 1.2-8µm | Coating: Uncoated |

|---|---|

| Diameter tolerance: ±0.2mm | Surface Quality: 60/40 |

| Thickness tolerance: ±0.1mm | Paralellism: <1 arc minute |

| Clear Aperture: 90% | Density: 2.329g/cm3 | Melting point: 1414ºC | Young's Modulus: (GPa): 51-80 | Coefficient of Thermal Expansion: 2.6 x 10-6/°C | Knoop Hardness: 1130kg/mm2 |

Expanded Silicon Properties:

| Chemical formula | Si |

|---|---|

| Crystal Class | Diamond |

| Resistivity, Ohm*cm | 5-40 | Molecular Weight | 28.0855 | Density, g/cm3 at 300 K | 2.33 | Dielectric Constant for 9.37 x 109 Hz at 300 K | 11.68 | Melting Temperature, K | 168 | Thermal Conductivity, W/(m K) at 293 K | 149 | Thermal Expansion, 1/K at 298 K | 2.6 x 10-6 | Bandgap, eV | 1.12 | Solubility in water | None | Knoop Hardness, kg/mm2 | 1150 | Mohs Hardness | 6.5 | Young's Modulus, GPa | 130-188 | Shear Modulus, GPa | 51-80 | Bulk Modulus, GPa | 97.6 | Poisson's Ratio | 0.28 |

Refractive Index of Silicon:

| µm | No |

|---|---|

| 2.0 | 3.456 |

| 4.0 | 3.429 |

| 6.0 | 3.424 |

Finding the right optical window can be an exercise in choice fatigue. Let us help!