Optical Windows

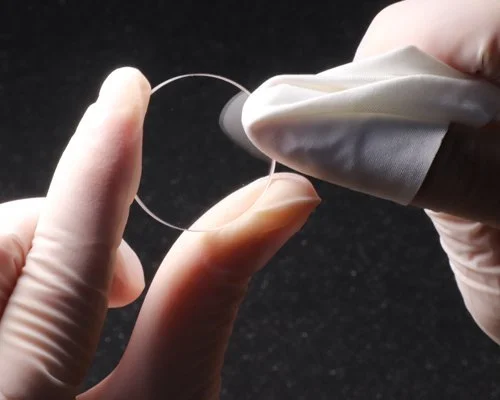

Optical windows are transparent components made of materials like glass or crystal that are used to protect and control the flow of light in optical systems. IR windows and optics for use in FTIR Spectroscopy and CO2 lasers. This includes discs, rectangular plates and various other geometries.

In various fields, optical windows serve many purposes. They act as protective barriers, shielding sensitive optical components from environmental factors such as dust, moisture, and contaminants. Additionally, they enable the transmission of light while minimizing distortion, reflection, and absorption, thus maintaining the integrity of the optical system.

Optical windows are employed in a wide range of applications, including scientific research, industrial manufacturing, aerospace, defense, and telecommunications. They are utilized in optical instruments like cameras, microscopes, telescopes, lasers, and sensors. By providing a stable optical interface, optical windows facilitate accurate measurements, imaging, and analysis of light, enabling advancements in numerous fields.

Optical windows come in many shapes and sizes but a major factor is their material. The types of materials that an optical window is constructed from dictate the wavelengths (measured in nm) that they can view. In IR It is extremely important that selecting the right material is done to avoid many a headache and a waste of money and time.

If you are having choice fatigue and are getting overwhelmed by all the options please check out our optical window guide.

Magnesium Fluoride (MgF2) Windows

Magnesium Fluoride (MgF2) Windows

Magnesium Fluoride or MgF2 has a superior transmission range of 120nm to 7μm, which covers all the way from the deep UV into the midwave-IR range.

Being one of the hardest fluoride materials, MgF2 is ideal for use in adverse, humid conditions and can withstand laser and chemical damage. This is a superior choice to other broadband materials like KBr , which also has good broadband tranmission coverage, but is hygroscopic and deteriorates in wet conditions.

Even with no optical coatings, MgF2 features a low surface reflectance and exceptional transmission.

If you do not see the configuration that you are looking for please contact us at info@firebirdoptics.com for a custom quote.

Magnesium Fluoride (MgF2) Specs:

Transmission of uncoated MgF2 windows:

General specs:

| Wavelength range: 1.2-8µm | Coating: Uncoated |

|---|---|

| Diameter tolerance: ±0.2mm | Surface Quality: 60/40 |

| Thickness tolerance: ±0.1mm | Paralellism: <1 arc minute |

| Clear Aperture: 90% | Density: 3.18g/cm3 | Melting point: 1255ºC | Young's Modulus: (GPa): 138 | Coefficient of Thermal Expansion: 13.7x 10-6/°C | Knoop Hardness: 415kg/mm2 |

Expanded Magnesium Fluoride Properties:

| Chemical formula | MgF2 |

|---|---|

| Crystal Class | Tetragonal, Rutile structure | Molecular Weight | 62.32 | Density, g/cm3 at 300 K | 3.1766 | Dielectric Constant for 9.37 x 109 Hz at 300 K | 4.87 | Melting Temperature, K | 1528 | Thermal Conductivity, W/(m K) at 293 K | 21 | Bandgap, eV | 10.8 | Solubility in water | None | Mohs Hardness | 4 | Shear Modulus, GPa | 54.66 | Bulk Modulus, GPa | 101.32 | Poisson's Ratio | 0.276 |

Refractive Index of MgF2:

| µm | No |

|---|---|

| 2.0 | 3.456 |

| 4.0 | 3.429 |

| 6.0 | 3.424 |

Magnesium Fluoride (MgF2) Windows: Foundations of Advanced Optical Engineering

Introduction

Magnesium Fluoride (MgF2) windows are indispensable in many cutting-edge fields, including aerospace, defense, spectroscopy, and medical imaging. Renowned for their exceptional optical properties, these windows support the transmission of ultraviolet (UV), visible, and infrared (IR) light. This article delves into the core features, applications, and advantages of MgF2 windows, offering insight into their role in modern optical systems.

What Are Magnesium Fluoride Windows?

MgF2 windows are precision-engineered optical components made from high-purity magnesium fluoride crystals. They excel in transmitting light across a broad spectral range, from deep ultraviolet (120 nm) to far-infrared (8 μm). Their mechanical strength and thermal stability make them ideal for demanding environments, such as high temperatures and pressures.

Magnesium fluoride is a birefringent material, meaning it can split light into two perpendicular polarized rays, which makes its alignment crucial in applications requiring minimal optical distortion. Additionally, its natural hardness and chemical inertness make it resistant to environmental degradation, ensuring long-term reliability.

Key Features of MgF2 Windows

Wide Spectral Transmission: Efficiently transmit light from UV to IR with minimal loss.

Robust Durability: Resistant to mechanical stress, thermal shock, and chemical degradation.

Minimal Birefringence: Reduce optical distortion, enabling precise imaging and measurements.

High Laser Damage Threshold: Withstand exposure to high-energy lasers.

Low Refractive Index: Enhances anti-reflective performance across the spectral range.

Applications of MgF2 Windows

Aerospace and Defense

In aerospace and defense, MgF2 windows are vital for optical systems that operate in extreme conditions. They are utilized in laser guidance, thermal imaging, and spectroscopic tools, where reliability and clarity are paramount for mission-critical applications. MgF2's ability to handle extreme temperatures and pressures makes it particularly suitable for aerospace sensors and instrumentation.

Spectroscopy

MgF2’s broad transmission range and VUV transparency make it ideal for spectroscopic analysis. These windows are pivotal in material science and chemical research, where high-resolution spectral data is crucial. The material's low absorption in the ultraviolet range enables precise analysis of light-sensitive samples and reactions.

Medical Imaging

Medical imaging devices frequently rely on MgF2 windows to operate in UV and IR ranges. Their high transmittance and low optical distortion ensure precise imaging, which is critical for accurate diagnostics and treatment planning. Applications include UV sterilization systems and IR-based thermal diagnostics.

Industrial and Scientific Research

From optical sensors to high-energy laser systems, MgF2 windows are integral in laboratory and industrial settings. Their ability to withstand intense power levels while maintaining consistent performance makes them a trusted choice for researchers and engineers. MgF2 is often used in laser systems for welding, cutting, and engraving, where optical clarity and durability are essential.

Environmental and Remote Sensing

In remote sensing and environmental monitoring, MgF2 windows protect sensitive optical instruments from harsh conditions while ensuring high transmission rates. These windows are ideal for satellite sensors and ground-based monitoring equipment, where long-term exposure to UV radiation and fluctuating temperatures is common.

Advantages of Magnesium Fluoride Windows

Broad Spectral Coverage: Spanning 120 nm to 8 μm, MgF2 windows support diverse optical applications.

Thermal and Mechanical Resilience: Perform reliably under extreme environmental conditions.

Long-Lasting Durability: Scratch-resistant surfaces reduce maintenance needs and improve longevity.

Customizable Options: Available in tailored sizes, shapes, and coatings for specialized applications.

Chemical Stability: Resistant to moisture, acids, and other corrosive substances, ensuring long-term performance.

Cost-Effectiveness: Offers high performance at a competitive cost, especially for bulk applications.

Choosing the Right MgF2 Windows

To select the appropriate MgF2 windows, consider:

Specific Use Case: Transmission range, environmental durability, and thermal stability requirements.

Coating Requirements: Anti-reflective coatings can optimize performance for targeted wavelengths. MgF2's natural low refractive index makes it compatible with additional coatings to further minimize reflection.

Custom Dimensions: Ensure compatibility with unique system designs through bespoke fabrication. Vendors often provide options for precise machining to meet exact application needs.

Conclusion

Magnesium Fluoride windows represent a cornerstone of optical technology, combining transparency, durability, and adaptability to meet the needs of advanced applications. Their broad use in fields such as aerospace, spectroscopy, and medical imaging underscores their significance in driving innovation. As technology evolves, MgF2 windows will continue to play a pivotal role in enabling precision and performance in optical systems.

Whether you need protection for delicate sensors, components for high-energy laser systems, or tools for cutting-edge spectroscopy, MgF2 windows deliver unmatched reliability and optical clarity. For further information or to explore custom MgF2 solutions, contact us and learn how these components can elevate your optical applications.

Finding the right optical window can be an exercise in choice fatigue. Let us help!