Optical Windows

Optical windows are transparent components made of materials like glass or crystal that are used to protect and control the flow of light in optical systems. IR windows and optics for use in FTIR Spectroscopy and CO2 lasers. This includes discs, rectangular plates and various other geometries.

In various fields, optical windows serve many purposes. They act as protective barriers, shielding sensitive optical components from environmental factors such as dust, moisture, and contaminants. Additionally, they enable the transmission of light while minimizing distortion, reflection, and absorption, thus maintaining the integrity of the optical system.

Optical windows are employed in a wide range of applications, including scientific research, industrial manufacturing, aerospace, defense, and telecommunications. They are utilized in optical instruments like cameras, microscopes, telescopes, lasers, and sensors. By providing a stable optical interface, optical windows facilitate accurate measurements, imaging, and analysis of light, enabling advancements in numerous fields.

Optical windows come in many shapes and sizes but a major factor is their material. The types of materials that an optical window is constructed from dictate the wavelengths (measured in nm) that they can view. In IR It is extremely important that selecting the right material is done to avoid many a headache and a waste of money and time.

If you are having choice fatigue and are getting overwhelmed by all the options please check out our optical window guide.

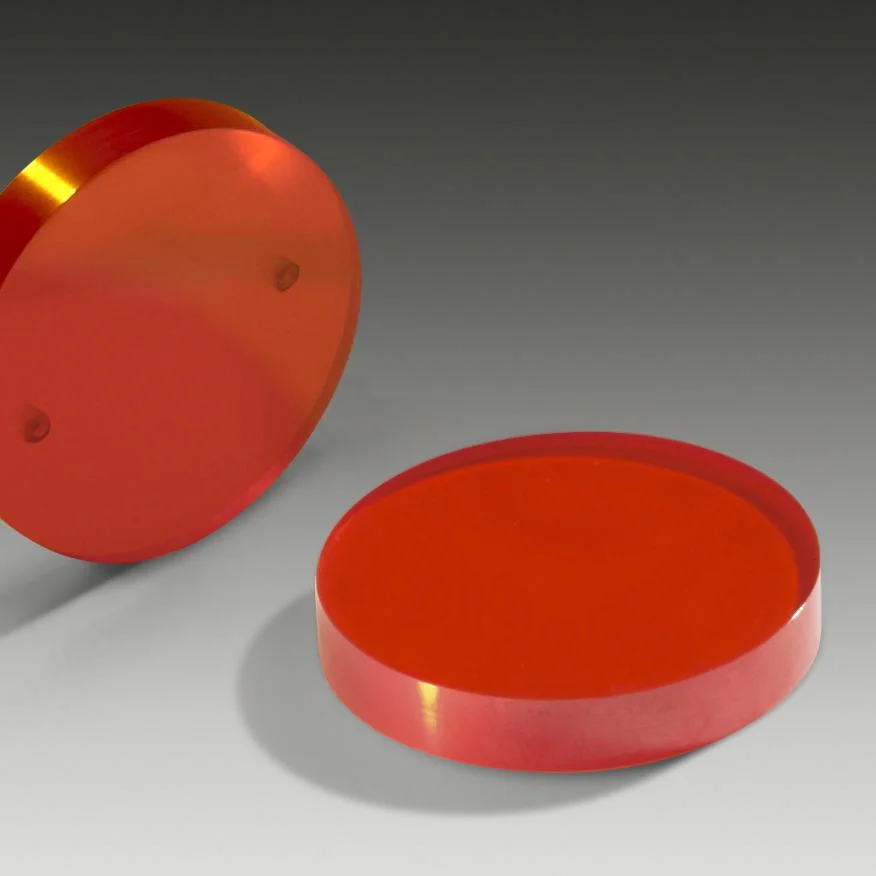

Thallium Bromoiodide (KRS-5) Windows

Thallium Bromoiodide (KRS-5) Windows

KRS-5 windows are optical windows made from a compound known as KRS-5, which is a type of thallium bromide-iodide (TlBr-TlI) crystal. These windows are primarily used in the field of infrared spectroscopy and imaging due to their excellent transparency in the mid-wave infrared (MWIR) and long-wave infrared (LWIR) regions ranging from 0.6-50µm.

The key features of KRS-5 windows include their wide spectral range, high refractive index, thermal stability, and chemical resistance. They cover a broad range of infrared wavelengths, making them suitable for various molecular absorption and emission studies. The high refractive index reduces reflection losses, ensuring efficient transmission of infrared light. KRS-5 windows can withstand elevated temperatures without significant degradation, making them reliable in high-temperature environments. Additionally, they are chemically stable, enabling compatibility with a variety of solvents, acids, and bases.

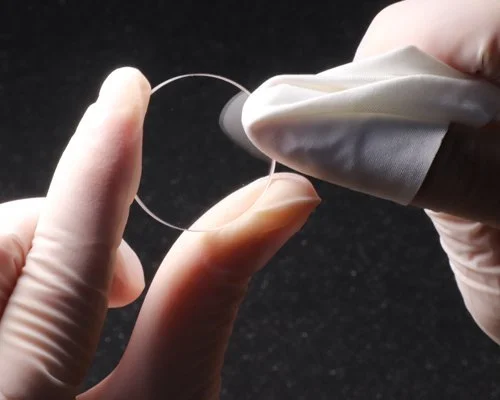

Extreme care must be used while handling KRS-5 windows as they are highly toxic. Gloves should be worn and hands should be thoroughly washed after handling the optics.

If you do not see the configuration that you are looking for please contact us at info@firebirdoptics.com for a custom quote.

KRS-5 Windows: Infrared Transparency and Applications

KRS-5 windows are optical windows made from a thallium bromide-iodide compound called KRS-5. These windows are specifically designed for use in infrared spectroscopy and imaging applications. With their exceptional transparency in the mid-wave infrared (MWIR) and long-wave infrared (LWIR) regions, KRS-5 windows enable accurate analysis and detection of infrared light.

Key Features and Characteristics:

Infrared Transparency: KRS-5 windows exhibit high transparency in the infrared wavelength range, typically spanning from 0.6 to 50 micrometers (µm). This transparency allows for the precise measurement and examination of infrared radiation.

Spectral Range: KRS-5 windows cover a broad spectral range within the infrared spectrum, making them ideal for applications requiring transmission in the MWIR and LWIR regions. These regions are critical for studying molecular absorption and emission features.

Refractive Index: With a relatively high refractive index in the infrared range, KRS-5 windows minimize reflection losses and maximize the efficiency of infrared light transmission through the material.

Thermal Stability: KRS-5 exhibits good thermal stability, enabling it to withstand high temperatures without significant degradation. This thermal resilience makes KRS-5 windows suitable for applications involving elevated temperatures.

Chemical Resistance: KRS-5 is chemically resistant, allowing it to withstand exposure to a wide range of solvents, acids, and bases without significant damage or degradation. This chemical stability contributes to the durability of KRS-5 windows.

Machinability: KRS-5 is a relatively soft material, making it easier to machine and shape into desired window forms. This property facilitates the manufacturing process of KRS-5 windows and allows for customization in terms of shape and size

Comparisons to Other Materials:

Silicon (Si): Silicon is widely used in the infrared region, particularly for its transparency in the MWIR and LWIR ranges. While silicon has better mechanical strength compared to KRS-5, it has limited transparency beyond 8-12 µm, which restricts its applicability in certain infrared applications.

Zinc Selenide (ZnSe): ZnSe is another popular material for infrared windows due to its wide transparency range from the visible to the LWIR region. It offers good mechanical strength but has limited transmission beyond 16 µm, unlike KRS-5.

Germanium (Ge): Germanium is well-suited for applications in the MWIR and LWIR regions due to its high refractive index and excellent transmission. However, germanium is more expensive and less chemically resistant compared to KRS-5.

Calcium Fluoride (CaF2): CaF2 provides excellent transmission in the ultraviolet, visible, and infrared regions. While it is mechanically strong, its transmission range in the infrared is limited compared to KRS-5.

Overall, KRS-5 windows offer unique advantages in terms of their broad infrared transparency, thermal stability, and chemical resistance. However, they have lower mechanical strength compared to some other materials. The choice of window material depends on the specific application requirements, including the desired wavelength range, mechanical robustness, and environmental compatibility.

Thallium Bromoiodide (KRS-5) Specs:

Transmission of uncoated KRS-5 windows:

General specs:

| Wavelength range: 600nm-40µm | Coating: Uncoated |

|---|---|

| Diameter tolerance: ±0.2mm | Surface Quality: 60/40 |

| Thickness tolerance: ±0.1mm | Paralellism: <1 arc minute |

| Clear Aperture: 85% | Density: 7.371g/cm3 | Melting point: 414.5ºC | Young's Modulus: (GPa): 15.85 | Coefficient of Thermal Expansion: 58x 10-6/°C | Knoop Hardness: 40.2g/mm2 |

Index of Refraction:

| µm | No |

|---|---|

| 1.0 | 2.44620 |

| 5.0 | 2.37979 |

| 10.0 | 2.37069 |

| 20.0 | 2.34058 |

| 30.0 | 2.28867 |

| 40.0 | 2.21047 |

Finding the right optical window can be an exercise in choice fatigue. Let us help!