Optical Windows

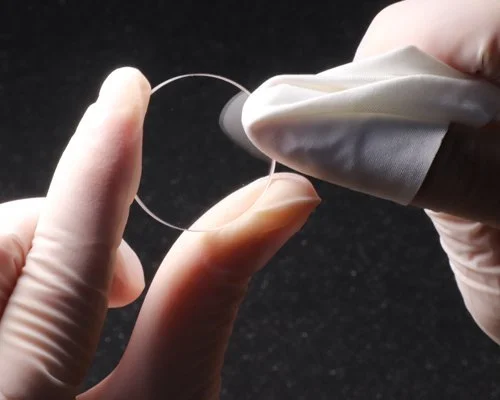

Optical windows are transparent components made of materials like glass or crystal that are used to protect and control the flow of light in optical systems. IR windows and optics for use in FTIR Spectroscopy and CO2 lasers. This includes discs, rectangular plates and various other geometries.

In various fields, optical windows serve many purposes. They act as protective barriers, shielding sensitive optical components from environmental factors such as dust, moisture, and contaminants. Additionally, they enable the transmission of light while minimizing distortion, reflection, and absorption, thus maintaining the integrity of the optical system.

Optical windows are employed in a wide range of applications, including scientific research, industrial manufacturing, aerospace, defense, and telecommunications. They are utilized in optical instruments like cameras, microscopes, telescopes, lasers, and sensors. By providing a stable optical interface, optical windows facilitate accurate measurements, imaging, and analysis of light, enabling advancements in numerous fields.

Optical windows come in many shapes and sizes but a major factor is their material. The types of materials that an optical window is constructed from dictate the wavelengths (measured in nm) that they can view. In IR It is extremely important that selecting the right material is done to avoid many a headache and a waste of money and time.

If you are having choice fatigue and are getting overwhelmed by all the options please check out our optical window guide.

Gallium Arsenide (GaAs) Windows

Gallium Arsenide (GaAs) Windows

Gallium Arsenide (GaAs) is a rugged material whose hardness and strength are called upon for IR measurements and as an alternative to the much softer ZnSe material, which has a similar transmission. With a transmission range of 1-16μm, GaAs is typically used in medium and high powered CO2 laser system as lenses and windows.

Additionally, GaAs is water insoluble and is chemically stable, which is good for versatility. The trade-off is that the material is toxic and must be handled with care.

Firebird provides these in several uncoated stock configurations but can provide customized and coated to your specifications.

Gallium Arsenide Optical Windows: The Full Breakdown

Gallium Arsenide (GaAs) optical windows are critical components used in various applications that require the transmission of infrared radiation. These windows exhibit excellent transparency in the mid-wave infrared (MWIR) and long-wave infrared (LWIR) regions, making them suitable for applications such as thermal imaging, infrared spectroscopy, and sensing. This report aims to explore the characteristics, advantages, and disadvantages of GaAs optical windows.

Gallium Arsenide (GaAs) optical windows are critical components used in various applications that require the transmission of infrared radiation. These windows exhibit excellent transparency in the mid-wave infrared (MWIR) and long-wave infrared (LWIR) regions, making them suitable for applications such as thermal imaging, infrared spectroscopy, and sensing. This report aims to explore the characteristics, advantages, and disadvantages of GaAs optical windows.

Characteristics of GaAs Optical Windows

Transparency: GaAs windows offer exceptional transparency in the infrared region of the electromagnetic spectrum, particularly in the MWIR and LWIR ranges. This property enables efficient transmission of infrared radiation, making GaAs windows valuable for thermal imaging and other related applications.

Thermal Stability: GaAs possesses high thermal stability and can withstand elevated temperatures without significant deformation or degradation. This characteristic is particularly advantageous in applications where exposure to high temperatures is common, such as in aerospace and defense systems.

Low Optical Absorption: GaAs windows exhibit low optical absorption in the infrared region. This property ensures minimal loss of light during transmission, allowing for high-quality imaging and accurate measurements in infrared spectroscopy and sensing applications.

Mechanical Strength: GaAs windows demonstrate excellent mechanical strength and hardness, making them resistant to scratching, wear, and impact. These attributes contribute to their suitability for use in demanding environments.

Wide Bandgap: GaAs possesses a wide bandgap, resulting in low intrinsic carrier concentration and dark current. This property makes GaAs windows ideal for optoelectronic applications, including solar cells, light-emitting diodes (LEDs), and photodetectors.

Advantages of Gallium Arsenide (GaAs) Optical Windows Compared to Zinc Selenide and Germanium:

Infrared Transparency: GaAs windows exhibit superior infrared transparency, especially in the mid-wave infrared (MWIR) and long-wave infrared (LWIR) regions. Compared to Zinc Selenide (ZnSe) and Germanium (Ge), GaAs windows offer better transmission characteristics in the infrared spectrum.

Thermal Stability: GaAs optical windows possess excellent thermal stability and can withstand high temperatures without significant deformation or degradation. This thermal resistance is often superior to ZnSe and Ge, making GaAs windows more suitable for applications involving elevated temperatures.

Mechanical Strength: GaAs windows demonstrate robust mechanical strength and resistance to scratching, wear, and impact. In comparison, ZnSe and Ge windows are relatively softer and more prone to damage.

Wide Bandgap Applications: GaAs has a wide bandgap, making it suitable for various optoelectronic applications, including solar cells, LEDs, and photodetectors. This advantage is not as pronounced in ZnSe and Ge, limiting their application range in certain optoelectronic devices.

Disadvantages of GaAs Optical Windows Compared to Zinc Selenide and Germanium:

Cost: GaAs is generally more expensive than ZnSe and Ge. The manufacturing cost of GaAs optical windows can be higher, which may be a disadvantage when cost is a significant factor in the application.

Limited Spectral Range: While GaAs windows excel in the infrared region, their transparency decreases significantly in the visible and ultraviolet ranges. In contrast, ZnSe has good transmission in the visible spectrum, and Ge performs well in both the visible and infrared regions.

Brittle Nature: GaAs is a brittle material, making GaAs windows susceptible to fracturing under stress or impact. In comparison, ZnSe and Ge are relatively more durable and less prone to breakage.

Refractive Index: GaAs has a lower refractive index compared to ZnSe and Ge. This lower refractive index can present challenges in optical system design that requires specific refractive index matching or control.

It is important to consider these advantages and disadvantages when selecting optical windows for a particular application. The specific requirements, such as spectral range, mechanical durability, thermal stability, and cost considerations, should guide the choice of the most appropriate material.

Conclusion

Gallium Arsenide (GaAs) optical windows offer numerous advantages, including infrared transparency, thermal stability, low optical absorption, mechanical strength, and wide bandgap applications. These characteristics make them valuable for various applications in thermal imaging, infrared spectroscopy, sensing, and optoelectronics. However, GaAs windows also have limitations, such as their cost, brittleness, limited spectral range, surface sensitivity, and lower refractive index. These factors must be considered when selecting GaAs windows for specific applications. Overall, GaAs optical windows provide a reliable and efficient solution for infrared transmission and are widely utilized in diverse industries.

| Wavelength range: 1-16µm | Coating: Uncoated |

|---|---|

| Diameter tolerance: ±0.13mm | Surface Quality: 60/40 |

| Thickness tolerance: ±0.13mm | Paralellism: <3 arc minute |

| Clear Aperture: 90% | Density: 5.32/cm3 | Melting point: 1511ºC | Young's Modulus: (GPa): 85 | Coefficient of Thermal Expansion: 5.7 x 10-6/°C | Knoop Hardness: 750kg/mm2 |

Finding the right optical window can be an exercise in choice fatigue. Let us help!