Optical Windows

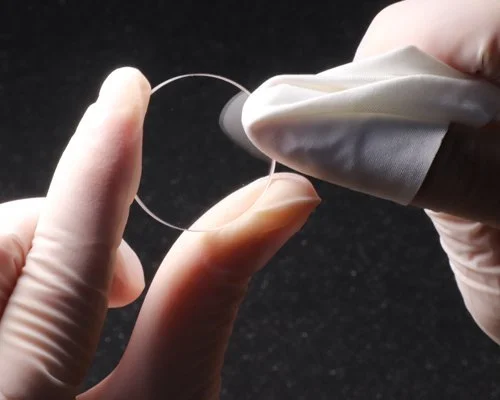

Optical windows are transparent components made of materials like glass or crystal that are used to protect and control the flow of light in optical systems. IR windows and optics for use in FTIR Spectroscopy and CO2 lasers. This includes discs, rectangular plates and various other geometries.

In various fields, optical windows serve many purposes. They act as protective barriers, shielding sensitive optical components from environmental factors such as dust, moisture, and contaminants. Additionally, they enable the transmission of light while minimizing distortion, reflection, and absorption, thus maintaining the integrity of the optical system.

Optical windows are employed in a wide range of applications, including scientific research, industrial manufacturing, aerospace, defense, and telecommunications. They are utilized in optical instruments like cameras, microscopes, telescopes, lasers, and sensors. By providing a stable optical interface, optical windows facilitate accurate measurements, imaging, and analysis of light, enabling advancements in numerous fields.

Optical windows come in many shapes and sizes but a major factor is their material. The types of materials that an optical window is constructed from dictate the wavelengths (measured in nm) that they can view. In IR It is extremely important that selecting the right material is done to avoid many a headache and a waste of money and time.

If you are having choice fatigue and are getting overwhelmed by all the options please check out our optical window guide.

Fused Silica (UV) Windows

Fused Silica (UV) Windows

UV Fused Silica is the standard bearer for UV/VIS applications. Compared to Optical Glass, Fused Silica can be used at higher temperatures (up to 1050ºC) and at wavelengths deeper into the UV range (180nm).

With excellent chemical resistance, resistance to thermal shock, hardness and durability, this is a common choice for aerospace, scientific instrumentation and industrial applications.

Firebird provides these in several uncoated stock configurations but can provide customized and coated to your specifications.

Fused Silica (UV) Window Specs:

| Wavelength range: 190-2,500nm | Coating: Uncoated |

|---|---|

| Diameter tolerance: +/-0.1mm | Surface Quality: 60/40 |

| Thickness tolerance: ±0.2mm | Paralellism: <1 arc minute |

| Clear Aperture: 90% | Density: 2.201g/cm3 | Melting point: 1585ºC | Young's Modulus: (GPa): 72.7 | Coefficient of Thermal Expansion: 5.7 x 10-6/°C | Knoop Hardness: 522kg/mm2 |

The Basics of Fused Silica (UV) Windows:

Fused silica windows are highly transparent optical components made from fused silica, a pure form of quartz glass. They are used in a variety of applications due to their unique properties and characteristics.

One of the main advantages of fused silica windows is their high transmission in the ultraviolet (UV), visible, and infrared (IR) spectrums, making them ideal for use in optical systems. They have a high level of optical clarity and low levels of absorption, scatter and refractive index variations, which makes them suitable for applications that require high precision and accuracy.

Fused silica windows are also known for their low thermal expansion coefficient, which means that they exhibit minimal change in their physical dimensions when exposed to changes in temperature. This makes them ideal for use in high-temperature environments, such as in laser systems, where stability is crucial. They are also highly resistant to thermal shock, which makes them ideal for use in applications that require rapid temperature changes.

In addition to their optical and thermal properties, fused silica windows are also highly durable and stable. They are resistant to mechanical, chemical, and UV degradation, making them ideal for use in harsh environment applications. They are also highly resistant to abrasion, making them ideal for use in applications that require frequent handling and cleaning.

Material Features of Fused Silica Windows:

UV fused silica windows are made of a highly pure form of quartz glass, known as fused silica. The following are some of the material characteristics of UV fused silica windows:

Optical Transparency: UV fused silica windows have high transmission in the ultraviolet (UV) spectrum, making them ideal for use in UV optical systems. They have low levels of absorption and scatter, providing high levels of optical clarity.

Thermal Stability: UV fused silica windows have a low thermal expansion coefficient, meaning that they exhibit minimal change in their physical dimensions when exposed to temperature changes. They are also highly resistant to thermal shock, making them ideal for use in high-temperature environments.

Chemical Stability: UV fused silica windows are highly resistant to chemical attack, making them ideal for use in applications that require exposure to harsh chemicals.

Mechanical strength: UV fused silica windows have high mechanical strength and durability, making them ideal for use in harsh environment applications. They are also highly resistant to abrasion, making them ideal for use in applications that require frequent handling and cleaning.

UV resistance: UV fused silica windows are highly resistant to UV degradation, making them ideal for use in applications that require exposure to UV radiation.

Dimensional stability: UV fused silica windows exhibit minimal change in their physical dimensions when exposed to changes in temperature and pressure, making them ideal for use in high-precision applications.

Advantages of UV Fused Silica Windows:

High UV transmission: UV fused silica windows have high transmission in the ultraviolet (UV) spectrum, making them ideal for use in UV optical systems.

Low thermal expansion: UV fused silica windows have a low thermal expansion coefficient, meaning that they exhibit minimal change in their physical dimensions when exposed to temperature changes.

Chemical stability: UV fused silica windows are highly resistant to chemical attack, making them ideal for use in applications that require exposure to harsh chemicals.

Mechanical strength: UV fused silica windows have high mechanical strength and durability, making them ideal for use in harsh environment applications.

UV resistance: UV fused silica windows are highly resistant to UV degradation, making them ideal for use in applications that require exposure to UV radiation.

Dimensional stability: UV fused silica windows exhibit minimal change in their physical dimensions when exposed to changes in temperature and pressure, making them ideal for use in high-precision applications.

Disadvantages of UV Fused Silica Windows:

Cost: UV fused silica windows can be relatively expensive compared to other optical materials such as optical glass, due to the high purity of the fused silica used in their manufacture.

Manufacturing complexity: The manufacturing process for UV fused silica windows can be complex and requires specialized equipment, making them more challenging to produce than other optical materials.

Fragility: UV fused silica windows can be brittle and prone to breaking when subjected to mechanical stress, making them less suitable for applications that require high mechanical robustness.

Overall, UV fused silica windows have a range of advantages and disadvantages that make them ideal for use in specific applications. The key is to carefully consider the specific requirements of each application and choose the right material to meet those requirements.