Optical Windows

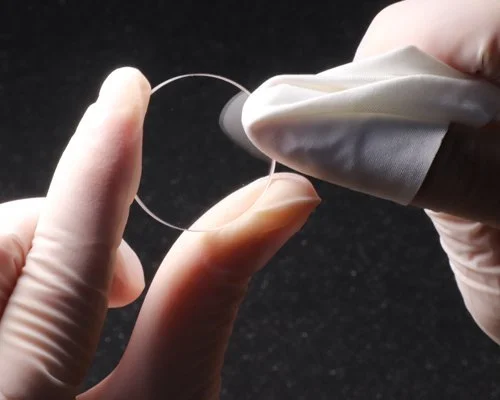

Optical windows are transparent components made of materials like glass or crystal that are used to protect and control the flow of light in optical systems. IR windows and optics for use in FTIR Spectroscopy and CO2 lasers. This includes discs, rectangular plates and various other geometries.

In various fields, optical windows serve many purposes. They act as protective barriers, shielding sensitive optical components from environmental factors such as dust, moisture, and contaminants. Additionally, they enable the transmission of light while minimizing distortion, reflection, and absorption, thus maintaining the integrity of the optical system.

Optical windows are employed in a wide range of applications, including scientific research, industrial manufacturing, aerospace, defense, and telecommunications. They are utilized in optical instruments like cameras, microscopes, telescopes, lasers, and sensors. By providing a stable optical interface, optical windows facilitate accurate measurements, imaging, and analysis of light, enabling advancements in numerous fields.

Optical windows come in many shapes and sizes but a major factor is their material. The types of materials that an optical window is constructed from dictate the wavelengths (measured in nm) that they can view. In IR It is extremely important that selecting the right material is done to avoid many a headache and a waste of money and time.

If you are having choice fatigue and are getting overwhelmed by all the options please check out our optical window guide.

Fused Silica (UV) Brewster Windows

Fused Silica (UV) Brewster Windows

Brewster windows are optical components designed to minimize reflection of light at a specific angle of incidence, known as Brewster's angle. These windows are crucial in laser systems and optical setups where controlling polarization and reducing unwanted reflections are essential. By allowing light with a specific polarization to pass through while minimizing reflections, Brewster windows play a pivotal role in enhancing optical performance and efficiency.

These windows are made from UV Fused Silica is the standard bearer for UV/VIS applications. Compared to Optical Glass, Fused Silica can be used at higher temperatures (up to 1050ºC) and at wavelengths deeper into the UV range (180nm). You can also check our standard non-Brewster UV Fused Silica Windows.

With excellent chemical resistance, resistance to thermal shock, hardness and durability, this is a common choice for aerospace, scientific instrumentation and industrial applications.

Firebird provides these in several uncoated stock configurations but can provide customized and coated to your specifications.

Fused Silica (UV) Brewster Window Specs:

Minor Diameter Options: 8 or 16mm

Minor Diameter Tolerance: 0+/-0.1mm

Thickness: 1 or 2mm

Thickness tolerance: +/-0.1mm

Brewster’s Angle: 55º32’ @ 633nm

| Wavelength range: 190-2,500nm | Coating: Uncoated |

|---|---|

| Diameter tolerance: +/-0.1mm | Surface Quality: 60/40 |

| Thickness tolerance: ±0.2mm | Paralellism: <1 arc minute |

| Clear Aperture: 90% | Density: 2.201g/cm3 | Melting point: 1585ºC | Young's Modulus: (GPa): 72.7 | Coefficient of Thermal Expansion: 5.7 x 10-6/°C | Knoop Hardness: 522kg/mm2 |

Polarization Mastery: Unraveling Brewster Windows and Their Optical Significance

In the realm of optics, where precision reigns supreme, Brewster windows emerge as a sophisticated innovation named after the visionary Sir David Brewster. This article embarks on an enlightening exploration of Brewster windows, delving into their crucial role in polarization control, reflection minimization, and their profound impact on optimizing optical systems.

Decoding Brewster Windows

Embedded within the intricate design of Brewster windows is a profound principle – the manipulation of light's polarization and reflection behavior. These specialized optical elements are meticulously engineered to transmit light at a specific angle called Brewster's angle, resulting in perfectly polarized reflected light. Composed primarily of dielectric materials, Brewster windows are strategically positioned to harness this distinctive phenomenon.

Polarization Precision

At the core of Brewster windows lies their remarkable ability to exert control over the polarization state of light. When light encounters a Brewster window at Brewster's angle, the reflected light becomes completely polarized, oriented perpendicular to the plane of incidence. This exceptional attribute finds wide-ranging applications in fields such as laser systems, optical communications, and spectroscopy, where meticulous polarization management is crucial for accurate measurements and optimal performance.

The Mathematics of Brewster's Angle

Brewster's angle, denoted as θB, is a fundamental optical angle that dictates the behavior of light when it strikes a dielectric surface. It is intricately tied to the refractive indices of the two media involved – the incident medium (usually air) and the refractive medium (such as glass or other dielectric materials). Mathematically, Brewster's angle is given by the arctangent of the ratio of the refractive indices: θB = arctan(n2 / n1), where n1 is the refractive index of the incident medium and n2 is the refractive index of the refractive medium.

The Brewster Effect: Polarization Control

At Brewster's angle, a remarkable phenomenon occurs: the reflected light becomes perfectly polarized. This means that the electric field vector of the reflected light is parallel to the plane of incidence. This property finds extensive use in controlling the polarization state of light. When light strikes a surface at Brewster's angle, the reflected light is polarized in a specific direction, enabling applications such as glare reduction and efficient optical communication.

Reflection Minimization: Brewster's Window

One of the most significant applications of Brewster's angle is in minimizing reflections. When light impinges on a dielectric surface at Brewster's angle, the intensity of the reflected light becomes zero for light polarized parallel to the plane of incidence. This property is exploited in the design of Brewster windows, which are placed in optical systems to minimize unwanted reflections. Brewster windows find extensive use in laser cavities, interferometers, and other optical setups where reflection reduction is critical for optimal performance.

Limitations and Considerations

While Brewster's angle offers remarkable benefits in polarization control and reflection reduction, it is important to note that it applies only to a specific polarization direction. For unpolarized light or light with different polarization orientations, the angle of incidence may need to be adjusted to achieve similar effects. Additionally, the refractive indices of materials can vary with wavelength, leading to the concept of the Brewster region, where Brewster's angle holds true for a range of wavelengths.

Conclusion

In the intricate realm of optics, Brewster's angle emerges as a mathematical gem with profound practical implications. Its ability to control polarization and minimize reflections has paved the way for innovations in optical technology, from laser systems to communications and beyond. As we navigate the intricate interplay of angles, refractive indices, and polarization states, Brewster's angle stands as a testament to the remarkable synergy between theory and application in the captivating world of optics.

Finding the right optical window can be an exercise in choice fatigue. Let us help!