Optical Mirrors

Optical mirrors are optical components with reflective surfaces, that are constructed in such a way as to reflect light waves in a specific way. These optics can be found in a variety of optical instruments, such as telescopes, microscopes, and laser systems.

Optical mirrors are typically made from a variety of materials including glass, metal, and plastic. They are typically coated with a thin layer of reflective material, such as aluminum or silver, to maximize their reflectivity.

There are several types of optical mirrors, including flat mirrors, concave mirrors, and convex mirrors. Flat mirrors reflect light waves in a straight line, while concave mirrors curve inward and focus light waves to a point. Convex mirrors, on the other hand, curve outward and spread light waves out.

Optical mirrors play a crucial role in many optical systems, allowing scientists and engineers to manipulate and direct light waves in a precise and controlled manner.

D-Shaped Mirrors

D-Shaped Mirrors

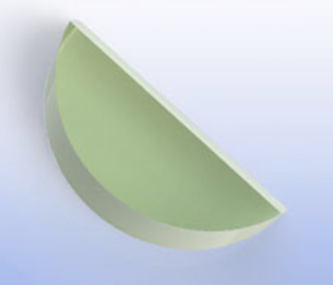

A D-shaped mirror is a type of mirror that has a curved surface on one side and a flat surface on the other side, forming a "D" shape. The curved side of the mirror is typically used to reflect and focus light, while the flat side can be used to reflect light at a 90-degree angle or as a mounting surface.

Firebird Optics D-Shaped mirrors are made from UV Fused silica substrate and available in a variety of different coatings.

D-Shaped Optical Mirrors: A Versatile Solution for Precision Optics

D-shaped optical mirrors are a unique and versatile type of mirror that finds applications in various fields of precision optics. Their distinctive shape and optical properties make them ideal for a wide range of optical systems and devices. In this article, we will explore the characteristics, applications, and advantages of d-shaped optical mirrors.

Understanding D-Shaped Optical Mirrors

D-shaped optical mirrors, as the name suggests, have a shape resembling the letter "D." They feature a flat reflective surface on one side and a curved surface on the other, which allows for the manipulation and control of light. The flat surface can be coated with reflective materials such as aluminum, silver, or dielectric coatings to enhance the mirror's reflective properties.

These mirrors are typically made from high-quality optical glass or precision-engineered materials like fused silica or Zerodur®. The choice of material depends on the specific application requirements, including factors like thermal stability, optical performance, and mechanical durability.

Applications of D-Shaped Optical Mirrors

D-shaped optical mirrors offer unique advantages that make them well-suited for various applications in precision optics. Here are some notable applications:

Laser Systems: D-shaped mirrors play a crucial role in laser systems. They can be used for beam steering, beam shaping, or as folding mirrors to redirect the laser beam's path. Their precise shape and high reflectivity enable efficient manipulation and control of laser light, ensuring optimal performance in applications such as laser marking, cutting, and engraving.

Imaging Systems: In imaging systems, d-shaped mirrors find applications in optical path folding, image rotation, and beam redirection. Their compact design and customizable shape allow for integration into compact imaging devices, such as endoscopes or periscopes. These mirrors also contribute to image quality by minimizing optical aberrations and maintaining precise alignment within the optical system.

Spectroscopy: Spectroscopic techniques often rely on d-shaped mirrors to direct and focus light onto detectors or through monochromators. The mirrors' shape and reflective coating ensure efficient light collection and transmission, enabling accurate spectral analysis and measurements. D-shaped mirrors are commonly used in fluorescence spectroscopy, Raman spectroscopy, and other analytical applications.

Advantages of D-Shaped Optical Mirrors

D-shaped optical mirrors offer several advantages that make them a preferred choice in precision optics:

Compact and Space-Efficient: the unique D-shape design allows for compact integration into optical systems, saving space and facilitating miniaturization. This is particularly beneficial in applications where size and weight constraints are critical, such as portable devices or space-constrained optical setups.

Enhanced Beam Control: the curved surface of d-shaped mirrors enables precise control over the direction and propagation of light. By adjusting the angle of incidence, the beam can be steered or redirected without requiring additional optical components. This enhances system simplicity and reduces potential sources of optical misalignment.

Versatility and Customizability: d-shaped mirrors offer a high degree of flexibility in terms of customization. The shape, size, and coatings can be tailored to meet specific application requirements. This adaptability allows for seamless integration into various optical systems, ensuring optimal performance and compatibility.

Cost-Effective Solution: compared to other complex optical components, d-shaped mirrors provide a cost-effective solution. Their simple design and ease of fabrication result in lower manufacturing costs, making them an attractive option for a wide range of optical applications.

Common Specifications for D-Shaped Mirrors:

Surface Quality: 40-20 Scratch Dig

Surface Flatness: λ/10 at 632.8 nm

Material: UV Fused Silica

Thickness: 6mm

Reflectivity Specs:

UV Aluminum (250-450nm)- Ravg: >90% from 250-450nm; AOI: 0º to 45º

Aluminum (450-700nm)- Ravg: >93%, Rmin>90% from 450-700nm; AOI: 0º to 45º

Silver (450nm-20μm)- Ravg: >97% from 450nm-2μm; Ravg >95% from 2-20μm; AOI: 0º to 45º

Gold (800nm-20μm)- Ravg:>96% from 800nm-20μm; AOI: 0º to 45º

Dielectric Coating (400-750nm)- Broadband HR, Rs.avg and Rp.avg: >99% from 400-750nm; AOI: 0º to 45º

Dielectric Coating (750-1100nm)- Broadband HR, Rs.avg and Rp.avg: >99% from 750-1100nm; AOI: 0º to 45º