Beam Splitters

Polarizing Beam Splitters are an optical device used in various applications to divide a beam of light into two separate beams with distinct polarization states. They are an important component in many optical systems, including microscopy, interferometry, laser systems, and telecommunications.

The basic function of a polarizing beam splitter is to transmit light of a certain polarization while reflecting light of orthogonal polarization. It splits an incoming unpolarized or randomly polarized light beam into two separate output beams: one that retains its original polarization and another that has its polarization perpendicular to the input polarization.

Polarizing beam splitters are constructed using birefringent materials or thin films that exploit the polarization-dependent reflection and transmission properties. The most common type of polarizing beam splitter is made using a combination of a dichroic prism or cube and a thin film polarizer.

The unpolarized or randomly polarized light enters the Polarizing Beam Splitter. The incoming light beam then encounters a dichroic plate, prism or cube, which is made of a birefringent material like calcite or other appropriate crystals. The crystal structure of these materials causes them to exhibit different refractive indices for light polarized parallel and perpendicular to a specific axis. In combination with the dichroic prism/cube, a thin film polarizer is often used to enhance the polarization separation. The thin film polarizer is designed to reflect one polarization state while transmitting the other.

As the light passes through the dichroic prism or cube, its polarization is split into two orthogonal components. One polarization component is transmitted through the prism/cube and the thin film polarizer, while the other polarization component is reflected by the thin film polarizer. The two polarized components of light exit the PBS as separate beams with distinct polarization states. One beam retains the original polarization, and the other beam has its polarization state rotated by 90 degrees.

Polarizing beam splitters are essential tools in optical systems where the separation or manipulation of polarized light is required. They find applications in polarimetry, imaging systems, laser setups, and other fields where precise control over polarization is necessary.

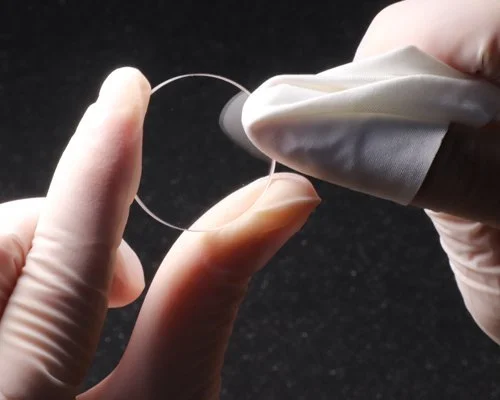

Firebird Optics offers them in both plate and cube configurations for both polarizing and non-polarizing applications. Beam splitters are constructed from high quality glass, calcite and other birefringent materials with tight tolerances on both surface flatness and quality, enabling them to be used in laser applications.

Glan-Taylor Polarizers

Glan-Taylor Polarizers

Firebird Optics’ Glan-Taylor Prisms or Glan-Taylor Polarizers are beamsplitters that split unpolarized light into two orthagonally polarized outputs. Comprised of an incident unpolarized or partially polarized light beam enters the crystal at one end. Due to the birefringence of the crystal, the light splits into two orthogonal polarization components as it travels through the crystal. These two components follow different optical paths within the crystal.

Glan-Taylor Prisms: An Introduction to Polarization Optics

Polarization optics is a branch of optics that deals with the manipulation and analysis of the polarization state of light. It is a fundamental aspect of modern optical technology and plays a crucial role in a wide range of applications, from astronomy and microscopy to telecommunications and medicine. A useful and specialized tool in polarization optics is the Glan-Taylor Prism, which is widely used for splitting and analyzing polarized light.

What is a Glan-Taylor Prism?

Glan-Taylor prisms, also known as Glan-Taylor polarizers, are optical devices used to polarize light. They are designed to transmit only light that vibrates in a specific polarization direction while blocking light that vibrates in other directions. Glan-Taylor prisms are commonly used in various scientific and industrial applications, including microscopy, spectroscopy, and laser systems. The basic design of a Glan-Taylor prism involves a birefringent crystal, often made of materials like calcite or alpha-BBO (beta barium borate). Birefringent materials have different refractive indices for light polarized along different axes. In a Glan-Taylor prism, an incident unpolarized or partially polarized light beam enters the crystal at one end. Due to the birefringence of the crystal, the light splits into two orthogonal polarization components as it travels through the crystal. These two components follow different optical paths within the crystal.

Working Principle of Glan-Taylor Prisms

The Glan-Taylor prism is cut and oriented in such a way that one of these polarization components is internally reflected multiple times within the crystal and eventually exits the prism, while the other component is absorbed or otherwise prevented from exiting. This results in a highly polarized output beam, with the polarization direction determined by the orientation of the crystal.

Traits of Glan-Taylor Prism

Key characteristics and advantages of Glan-Taylor prisms include:

High Polarization Efficiency: Glan-Taylor prisms can achieve high polarization purity, typically exceeding 99% for the transmitted polarization.

Broad Spectral Range: They can be used over a wide range of wavelengths, making them suitable for various applications.

Wide Acceptance Angle: Glan-Taylor prisms often have a wide acceptance angle, allowing them to accept light over a range of incident angles.

Low Dispersion: These prisms generally exhibit low chromatic dispersion, which means they don't significantly separate light of different wavelengths.

Durability: Glan-Taylor prisms are mechanically stable and robust, making them suitable for use in various environments.

Specs for Glan-Taylor Prisms:

Materials available: Alpha-Barium-Borate (α-BBO) and Calcite

Wavelength ranges: α-BBO: 200-3500nm, Calcite: 350-2300nm

Extinction ratio: α-BBO:<5×10-6, Calcite, <5×10-5

Surface Quality: 20-10

Beam Deviation: <3 arc minutes

Flatness: λ/4@633nm

Damage Threshold: >200MW/cm2

Coating: Single Layer MgF2

Holder: Black Anodized Aluminum