Beam Splitters

Polarizing Beam Splitters are an optical device used in various applications to divide a beam of light into two separate beams with distinct polarization states. They are an important component in many optical systems, including microscopy, interferometry, laser systems, and telecommunications.

The basic function of a polarizing beam splitter is to transmit light of a certain polarization while reflecting light of orthogonal polarization. It splits an incoming unpolarized or randomly polarized light beam into two separate output beams: one that retains its original polarization and another that has its polarization perpendicular to the input polarization.

Polarizing beam splitters are constructed using birefringent materials or thin films that exploit the polarization-dependent reflection and transmission properties. The most common type of polarizing beam splitter is made using a combination of a dichroic prism or cube and a thin film polarizer.

The unpolarized or randomly polarized light enters the Polarizing Beam Splitter. The incoming light beam then encounters a dichroic plate, prism or cube, which is made of a birefringent material like calcite or other appropriate crystals. The crystal structure of these materials causes them to exhibit different refractive indices for light polarized parallel and perpendicular to a specific axis. In combination with the dichroic prism/cube, a thin film polarizer is often used to enhance the polarization separation. The thin film polarizer is designed to reflect one polarization state while transmitting the other.

As the light passes through the dichroic prism or cube, its polarization is split into two orthogonal components. One polarization component is transmitted through the prism/cube and the thin film polarizer, while the other polarization component is reflected by the thin film polarizer. The two polarized components of light exit the PBS as separate beams with distinct polarization states. One beam retains the original polarization, and the other beam has its polarization state rotated by 90 degrees.

Polarizing beam splitters are essential tools in optical systems where the separation or manipulation of polarized light is required. They find applications in polarimetry, imaging systems, laser setups, and other fields where precise control over polarization is necessary.

Firebird Optics offers them in both plate and cube configurations for both polarizing and non-polarizing applications. Beam splitters are constructed from high quality glass, calcite and other birefringent materials with tight tolerances on both surface flatness and quality, enabling them to be used in laser applications.

Polarizing Plate Beamsplitters

Polarizing Plate Beamsplitters

Firebird Optics’ polarizing plate beamsplitters come with a variety of coatings for various laser wavelengths. Featuring a 45º angle of incidence, our polarizing beamsplitters transmit p-polarized light and reflect s-polarized light.

A Comprehensive Guide to Polarizing Plate Beamsplitters

What Are Polarizing Plate Beamsplitters?

Polarizing plate beamsplitters are specialized optical components designed to split an incoming beam of light into two separate beams based on their polarization state. Unlike non-polarizing beamsplitters, these components divide light into s-polarized (perpendicular) and p-polarized (parallel) beams with high precision and efficiency.

These beamsplitters are critical in optical systems where polarization control and manipulation are essential. In laser systems, they enable precise beam alignment and stabilization by managing the polarization states efficiently. In microscopy, they enhance image contrast and clarity by isolating specific polarization components, allowing researchers to explore molecular structures and material properties with exceptional detail. In telecommunications, these beamsplitters optimize data transmission by effectively handling polarized light in fiber optic networks, reducing signal loss and maintaining high data rates. Their ability to separate polarization states with minimal loss makes them invaluable for applications requiring precise light management. They are particularly favored in environments demanding high optical throughput, such as manufacturing, quantum computing, and high-energy physics.

Polarizing plate beamsplitters also find usage in fields like augmented and virtual reality, where maintaining polarization fidelity is crucial for enhancing image clarity and reducing optical artifacts. The growing integration of these components into advanced technologies highlights their role as indispensable tools for modern optical systems.

How Polarizing Plate Beamsplitters Work

Polarizing plate beamsplitters operate using advanced dielectric coatings applied to high-quality optical substrates. The coatings are carefully designed to reflect one polarization state (s-polarized) while transmitting the other (p-polarized). This separation occurs with minimal energy loss and high extinction ratios, ensuring efficient operation across a broad range of wavelengths.

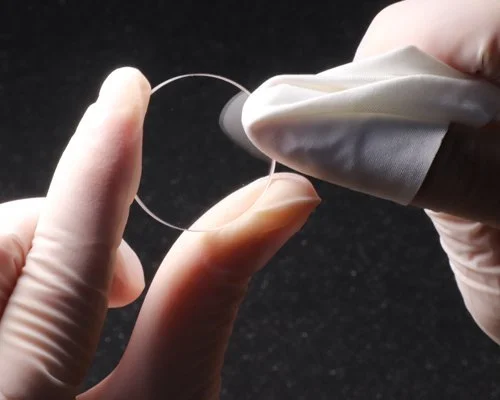

Typically, these beamsplitters are configured as thin, flat optical plates placed at a 45-degree angle to the incoming light. The dielectric coating selectively interacts with the polarization states, enabling a clean division of light into two distinct beams. Anti-reflective coatings are often applied to the non-coated surfaces to minimize losses and enhance overall efficiency. These coatings reduce unwanted reflections that can cause energy losses, ensuring that more light is either transmitted or reflected as needed, thereby maximizing the system's performance.

Recent advancements in dielectric coating technology have improved the performance of these beamsplitters, allowing them to operate effectively under extreme conditions, such as high laser power densities and temperature fluctuations. This makes them suitable for cutting-edge research and industrial applications.

Key Features of Polarizing Plate Beamsplitters

1. High Polarization Extinction Ratio

Polarizing beamsplitters are optimized to achieve a high extinction ratio, ensuring effective separation of s- and p-polarized light. This characteristic is crucial for maintaining the quality and fidelity of polarization-sensitive systems. Advanced designs enable these beamsplitters to deliver consistent performance even in multi-wavelength systems, such as those used in hyperspectral imaging. In this application, the beamsplitter can efficiently separate and manage multiple wavelength bands, enabling precise analysis of materials or biological samples across a broad spectral range.

2. Efficient Energy Management

These beamsplitters minimize energy loss during the separation process, enabling efficient operation in high-power laser systems and other demanding optical setups. Their superior energy management properties reduce heat-related distortions and enhance system longevity.

3. Broad Wavelength Compatibility

Polarizing plate beamsplitters can be designed to work within specific wavelength ranges or as broadband solutions, making them adaptable for various applications. Customization options allow for tailoring wavelength performance to meet specialized requirements, such as those found in biomedical imaging and aerospace technologies.

4. Precision Design

The plate configuration ensures a compact, lightweight design that integrates seamlessly into complex optical assemblies. Their minimal footprint is ideal for systems with space constraints, while their robust construction provides durability in demanding environments.

5. Thermal and Mechanical Stability

Modern polarizing beamsplitters are engineered to withstand significant thermal and mechanical stresses. This stability ensures reliable performance in dynamic conditions, such as those encountered in manufacturing or outdoor instrumentation.

Applications of Polarizing Plate Beamsplitters

1. Laser Systems

In laser systems, polarizing plate beamsplitters are used to control and manipulate polarized laser beams, ensuring precise alignment and intensity management. They are essential in creating optical isolators and modulators, which are crucial for maintaining laser coherence and stability.

2. Microscopy

Polarizing beamsplitters play a critical role in advanced microscopy techniques, such as polarization-sensitive imaging and confocal microscopy, where the separation of polarization states enhances image clarity and contrast. They also enable researchers to explore molecular structures and material properties with greater precision.

3. Optical Communication

In telecommunications, these beamsplitters are used to manage polarized light in fiber optic networks, contributing to efficient data transmission and processing. Their ability to handle high data rates and minimize signal loss makes them vital components in modern communication systems.

4. Research and Development

Polarizing plate beamsplitters are indispensable tools in scientific research, enabling experiments that require precise polarization control in optical systems. They are used in spectroscopy, quantum mechanics, and other fields requiring meticulous light manipulation.

5. Augmented and Virtual Reality

Emerging AR and VR technologies leverage polarizing plate beamsplitters to optimize light distribution and image quality. For example, in virtual reality headsets, these beamsplitters are used to manage polarized light for improved image contrast and color accuracy, creating a more immersive experience for users. These beamsplitters ensure immersive visual experiences by reducing polarization-induced distortions.

Firebird Optics Polarizing Plate Beamsplitters

At Firebird Optics, we provide high-performance polarizing plate beamsplitters tailored to meet the exacting standards of modern optical applications. Our beamsplitters are engineered with advanced dielectric coatings and precision manufacturing techniques to deliver exceptional reliability and performance.

Customization Options

We recognize that every application is unique. Firebird Optics offers:

Custom wavelength ranges to match your application’s needs.

High-quality substrates, including BK7 and fused silica.

Precise dimensions and thicknesses to ensure seamless integration.

Coatings optimized for specific environmental and operational requirements.

Quality Assurance

Every Firebird Optics product undergoes rigorous testing to meet or exceed industry standards. Our commitment to quality ensures reliable performance in the most demanding environments. We also provide extensive documentation and support to facilitate integration into your optical systems.

Why Choose Firebird Optics for Polarizing Plate Beamsplitters?

1. Expertise in Polarization Control

Our team brings years of experience in designing and manufacturing polarization-sensitive optics, ensuring the highest level of precision and efficiency in our beamsplitters. Our deep understanding of polarization physics allows us to tackle even the most complex optical challenges.

2. Tailored Solutions

We collaborate with you to develop customized solutions that align perfectly with your specific requirements, from wavelength selection to form factor. Whether you need beamsplitters for standard laboratory setups or highly specialized industrial systems, we deliver exactly what you need.

3. Commitment to Quality and Service

At Firebird Optics, we prioritize excellence in both product quality and customer service. Our responsive support team is ready to address your needs quickly and effectively. With a focus on long-term partnerships, we strive to provide unmatched reliability and satisfaction.

4. Competitive Pricing

We provide high-performance beamsplitters at competitive prices, delivering exceptional value for your investment. Our pricing model ensures that cutting-edge optical components are accessible to a wide range of industries and applications.