Beam Splitters

Polarizing Beam Splitters are an optical device used in various applications to divide a beam of light into two separate beams with distinct polarization states. They are an important component in many optical systems, including microscopy, interferometry, laser systems, and telecommunications.

The basic function of a polarizing beam splitter is to transmit light of a certain polarization while reflecting light of orthogonal polarization. It splits an incoming unpolarized or randomly polarized light beam into two separate output beams: one that retains its original polarization and another that has its polarization perpendicular to the input polarization.

Polarizing beam splitters are constructed using birefringent materials or thin films that exploit the polarization-dependent reflection and transmission properties. The most common type of polarizing beam splitter is made using a combination of a dichroic prism or cube and a thin film polarizer.

The unpolarized or randomly polarized light enters the Polarizing Beam Splitter. The incoming light beam then encounters a dichroic plate, prism or cube, which is made of a birefringent material like calcite or other appropriate crystals. The crystal structure of these materials causes them to exhibit different refractive indices for light polarized parallel and perpendicular to a specific axis. In combination with the dichroic prism/cube, a thin film polarizer is often used to enhance the polarization separation. The thin film polarizer is designed to reflect one polarization state while transmitting the other.

As the light passes through the dichroic prism or cube, its polarization is split into two orthogonal components. One polarization component is transmitted through the prism/cube and the thin film polarizer, while the other polarization component is reflected by the thin film polarizer. The two polarized components of light exit the PBS as separate beams with distinct polarization states. One beam retains the original polarization, and the other beam has its polarization state rotated by 90 degrees.

Polarizing beam splitters are essential tools in optical systems where the separation or manipulation of polarized light is required. They find applications in polarimetry, imaging systems, laser setups, and other fields where precise control over polarization is necessary.

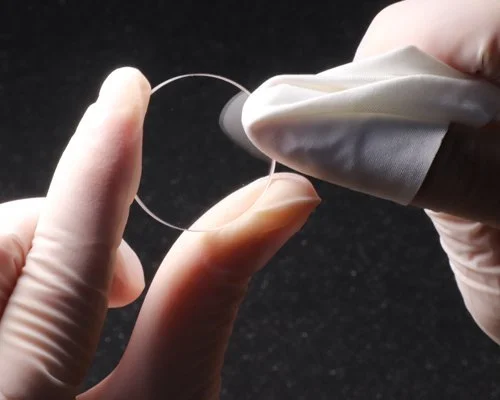

Firebird Optics offers them in both plate and cube configurations for both polarizing and non-polarizing applications. Beam splitters are constructed from high quality glass, calcite and other birefringent materials with tight tolerances on both surface flatness and quality, enabling them to be used in laser applications.

Broadband Polarizing Cube Beamsplitters

Broadband Polarizing Cube Beamsplitters

Broadband polarizing cube beamsplitters are the best option for use with multiple or tunable sources. Featuring dielectric beamsplitter coating and consisting of two right angle prisms, these cubes transmit p-polarized light and reflect s-polarized light.

Firebird Optics provides these cubes with a range of dimensions and optical coatings.

Features:

Excellent performance across a broad wavelength range

Dielectric antireflection coating to minimize surface reflection.

Comes in a variety of sizes ranging from 12.7-50.8mm.

Low wavefront distortion

Extinction ratio >500:1 with an average of 1000:1

Polarizing Beamsplitter Cubes: Navigating Light with Precision

Polarizing beamsplitter cubes stand as pragmatic tools in optics, offering a straightforward solution for separating polarized light based on its polarization state. These cubes utilize a combination of prisms and coatings to achieve efficient beam splitting, directing light of one polarization along a distinct path while allowing light of orthogonal polarization to pass through unaffected. Understanding the differences between polarizing and nonpolarizing cubes provides insights into their specific applications in diverse optical systems.

Polarizing vs. Nonpolarizing Cubes

Polarizing cubes are designed to split incident light into two orthogonal polarization components, typically denoted as s-polarization and p-polarization. In contrast, nonpolarizing cubes are engineered to split light without regard to its polarization state, making them suitable for applications where maintaining the original polarization is not a critical factor. The primary distinction lies in the coatings and prisms used within the cube, with polarizing cubes incorporating coatings that selectively transmit or reflect light based on polarization.

Practical Applications

1. Microscopy:

Polarizing beamsplitter cubes find applications in microscopy setups, where the separation of polarized light components is crucial for capturing specific information about samples.

2. Imaging Systems:

In imaging applications, these cubes contribute to the creation of polarization-sensitive images, enhancing the clarity and contrast of the captured visual data.

3. Interferometry:

The precision of polarizing cubes is harnessed in interferometry setups, where splitting and recombining polarized light paths are essential for accurate interference patterns.

4. Laser Systems:

Both polarizing and nonpolarizing cubes play integral roles in laser systems, facilitating beam splitting, combination, and polarization control for diverse applications.

Conclusion

Polarizing beamsplitter cubes offer practical solutions for managing polarized light in various optical systems. Whether splitting light for microscopy, enhancing imaging clarity, or enabling precise interference in interferometry, these cubes provide essential functionality. Understanding the distinction between polarizing and nonpolarizing cubes allows researchers and engineers to choose the appropriate tool for specific applications, ensuring efficient and reliable light manipulation in diverse optical setups.