Beam Splitters

Polarizing Beam Splitters are an optical device used in various applications to divide a beam of light into two separate beams with distinct polarization states. They are an important component in many optical systems, including microscopy, interferometry, laser systems, and telecommunications.

The basic function of a polarizing beam splitter is to transmit light of a certain polarization while reflecting light of orthogonal polarization. It splits an incoming unpolarized or randomly polarized light beam into two separate output beams: one that retains its original polarization and another that has its polarization perpendicular to the input polarization.

Polarizing beam splitters are constructed using birefringent materials or thin films that exploit the polarization-dependent reflection and transmission properties. The most common type of polarizing beam splitter is made using a combination of a dichroic prism or cube and a thin film polarizer.

The unpolarized or randomly polarized light enters the Polarizing Beam Splitter. The incoming light beam then encounters a dichroic plate, prism or cube, which is made of a birefringent material like calcite or other appropriate crystals. The crystal structure of these materials causes them to exhibit different refractive indices for light polarized parallel and perpendicular to a specific axis. In combination with the dichroic prism/cube, a thin film polarizer is often used to enhance the polarization separation. The thin film polarizer is designed to reflect one polarization state while transmitting the other.

As the light passes through the dichroic prism or cube, its polarization is split into two orthogonal components. One polarization component is transmitted through the prism/cube and the thin film polarizer, while the other polarization component is reflected by the thin film polarizer. The two polarized components of light exit the PBS as separate beams with distinct polarization states. One beam retains the original polarization, and the other beam has its polarization state rotated by 90 degrees.

Polarizing beam splitters are essential tools in optical systems where the separation or manipulation of polarized light is required. They find applications in polarimetry, imaging systems, laser setups, and other fields where precise control over polarization is necessary.

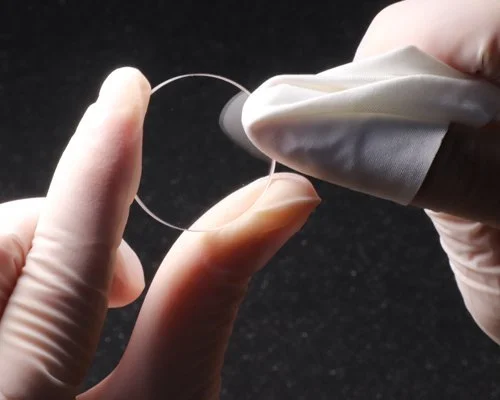

Firebird Optics offers them in both plate and cube configurations for both polarizing and non-polarizing applications. Beam splitters are constructed from high quality glass, calcite and other birefringent materials with tight tolerances on both surface flatness and quality, enabling them to be used in laser applications.

Non-Polarizing Plate Beamsplitters

Non-Polarizing Plate Beamsplitters

Firebird Optics non-polarizing Plate Beamsplitters come in either Calcium Fluoride (CaF2) or Zinc Selenide (ZnSe) and are designed for use in the wavelength range of 2-14μm.

These are commonly called 50/50 beamsplitters as these split a beam into two equal beams with a 50% +/- 10% splitting ratio.

Non-Polarizing Plate Beamsplitter Specs:

Available in CaF2 and ZnSe

High transmission in the IR range of 2-4 microns.

High thermal shock resistance

Can be conveniently mounted in standard mirror mounts

A Comprehensive Guide to Non-Polarizing Plate Beamsplitters

What Are Non-Polarizing Plate Beamsplitters?

Non-polarizing plate beamsplitters, often referred to as 50/50 beamsplitters, are optical components designed to divide an incoming beam of light into two separate beams with equal intensity, regardless of the polarization state of the light. Unlike polarizing beamsplitters that separate light based on polarization, non-polarizing beamsplitters are engineered to maintain the original polarization properties of the transmitted and reflected beams.

These beamsplitters are critical in applications where preserving the polarization state is essential, such as laser systems, imaging, and interferometry. They are commonly employed in laboratories, industrial applications, and optical setups requiring precise light manipulation.

How Non-Polarizing Beamsplitters Work

Non-polarizing beamsplitters rely on advanced dielectric coatings applied to optical substrates, such as glass or fused silica. These coatings are meticulously designed to achieve a 50/50 split of light intensity over a specific range of wavelengths while minimizing polarization-dependent losses.

The plate configuration involves a thin, flat optical element placed at an angle (typically 45 degrees) to the incoming light. When light strikes the coated surface, a portion is reflected while the remainder is transmitted, creating two beams of equal intensity. The performance of these beamsplitters is defined by factors such as wavelength range, angular tolerance, and the quality of the anti-reflective coatings on the uncoated surfaces.

Key Features of Non-Polarizing Plate Beamsplitters

1. Polarization Independence

Non-polarizing beamsplitters are specifically designed to split light without altering its polarization state. This feature makes them ideal for applications where polarization fidelity is critical.

2. High Transmission and Reflection Efficiency

Advanced dielectric coatings ensure a precise 50/50 split of light intensity with minimal losses, maximizing the efficiency of optical systems.

3. Broad Wavelength Compatibility

These beamsplitters can be optimized for specific laser lines (e.g., 532 nm, 1064 nm) or broadband light sources, making them versatile for a wide range of applications.

4. Compact Design

The plate configuration offers a compact and lightweight design, allowing easy integration into various optical systems.

Applications of Non-Polarizing Plate Beamsplitters

1. Laser Systems

In laser setups, non-polarizing beamsplitters are used for beam splitting, alignment, and directing laser light to multiple paths while preserving polarization integrity.

2. Interferometry

These beamsplitters are integral to interferometers, where accurate division of light is essential for creating interference patterns used in precise measurements.

3. Imaging and Microscopy

Non-polarizing beamsplitters play a crucial role in imaging systems, enabling simultaneous image capture and analysis without introducing polarization artifacts.

4. Spectroscopy

In spectroscopic applications, these beamsplitters are used to direct light beams into different optical paths for analysis.

Firebird Optics Non-Polarizing Plate Beamsplitters

Firebird Optics offers high-performance non-polarizing plate beamsplitters tailored to meet the rigorous demands of modern optical applications. Our beamsplitters are manufactured using advanced dielectric coatings and precision engineering to deliver exceptional performance and reliability.

Customization Options

We understand that every application is unique. That’s why Firebird Optics provides customization options for:

Wavelength range and coating design.

Substrate materials, such as BK7 or fused silica.

Dimensions and thickness specifications to fit your optical system.

Quality Assurance

All Firebird Optics beamsplitters undergo rigorous testing to ensure they meet or exceed industry standards. We are committed to providing products that deliver consistent, reliable results across a wide range of applications.